Tachometer

for a Sherline lathe

This

article assumes you have read Sherline Lathe

Infrastructure

I

decided to add a tachometer to my machined base Sherline

lathe when I was changing the lathe to use a stepper motor drive. (See separate article.) I found a very inexpensive solution.

I

used a tachometer system that included a NPN Hall proximity switch sensor and a

display for under $20. (See parts list

at end.)

I

drilled a 1/8 diameter hole in the inner pulley on the Sherline

headstock and glued a 1/8 inch diameter by ½ inch long

magnet in it. I never used the inner

pulley when I used the Sherline motor so this did not

interfere with normal operation. Since I

also switched to stepper motor drive for the lathe (see separate article) the

pulley was not used at all. The hole is just deep enough so that the tip of the

magnet is even with the sides of the pulley.

I used CA glue that claims to be designed to hold metal. (See figure 1.)

Figure 1: magnet

installed in pulley

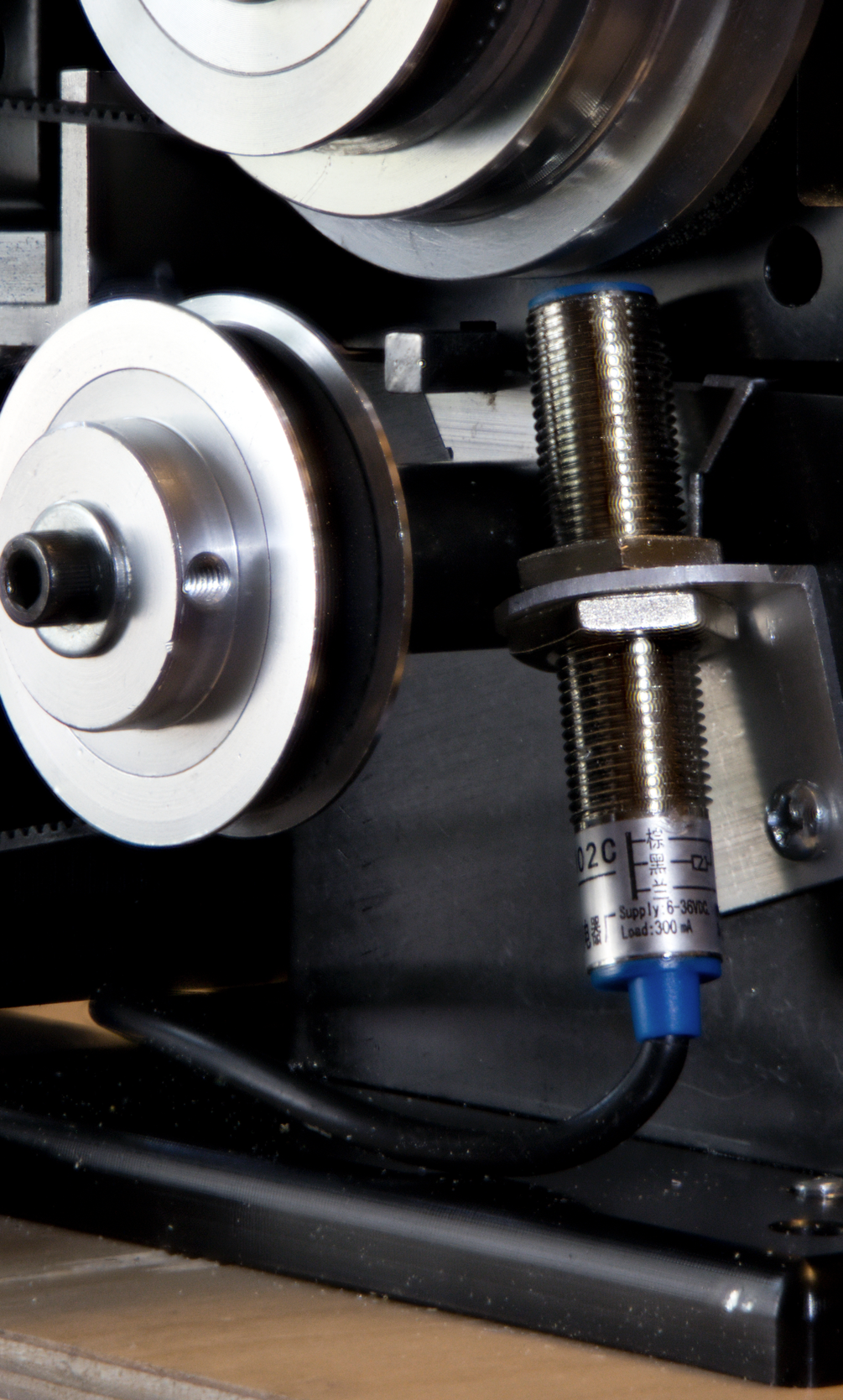

I

then made a small aluminum bracket to hold the sensor and mounted the sensor and

bracket on the side of the headstock pillar on the lathe base. I drilled and taped to 6-32 holes into the pillar

to hold the bracket. See figure 2.

Figure 2: Hall

effect sensor installed

I

drilled a hole in the lathe’s plywood base and ran the sensor cord through the

hole and connected the wires in the cable to a barrier strip that I had mounted

in the base. I then connected the wires

from the tachometer display module to the barrier strip. (I had to extend three

of the wires by soldering on short pieces of wire and protecting the connection

with shrink tube.) Running the cord under the plywood base ensured that the

cord would not trap chips and make cleanup harder. I then mounted the display on the control

module bracket under the lathe bed. (See

figure 3.)

Figure 3:

tachometer display installed

The

tachometer system that I used requires 24-volt DC power to run. In my case I had a 24-volt DC power supply connected

to the lathe for the stepper motor drive, so I just connected the tachometer

power leads to it. If you do not have 24

vdc handy you can get any one of a number of small power supplies, for

example.

There

are also models of the tachometer kit

that take 110-230 volts

AC directly, but that seems a bit tricky to use safely.

The

total cost, even if you have to get a separate power supply, is less than $50 –

easily worth the price.

Parts

list

Copyright

Ó 2024 Scott

Bradner

2024-09-05