Power

feed for Sherline lathe

This

article assumes you have read Sherline Lathe

Infrastructure.

I

wanted to add a power feed to my 17-inch Sherline

lathe to make machining easier and smoother.

This involved adding a stepper motor and some electronics to the

lathe. The stepper motor is used to turn

the lead screw as if the lead screw was being turned by the X axis handwheel.

Following

are instructions if you want to do the same.

At the end of the article is a parts list. I have included URLs for parts if you want to

get them from Amazon. The parts are also available from other sources if you

prefer. Note that this system would be a

tight fit on an 8-inch lathe. This setup

assumes that the lathe is mounted on a base as described in Hacks on a Sherline Lathe.

I

used a NEMA 23 stepper motor and mounting bracket, a TB6600 MIcrostep

Driver, a simple pulse generator, a small relay module and a DPDT (on)-off-(on)

switch. The stepper motor and TB6600

driver used 24 vdc so I used a 24 vdc power supply. The pulse generator, the relay and the TB6600

control signals required 5vdc so I also used a 24vdc to 5vdc converter.

The

relay module is needed because the TB6600 enable input (ENA) defaults to

enabled if there is nothing connected to it.

I connected the TB6600 ENA+ to the normally closed terminal on the relay

and +5vdc to the common terminal so that the default would be that the TB6600

is disabled. The switch drives the relay

such that the relay is engaged and the TB6600 is enabled when the DPDT switch

is switched to one side or the other.

This means that the stepper motor does not run when the switch is in the

center (off) position but does run when the switch is moved to the left or to

the right. The other terminals on the switch are used to

send +5vdc to the DIR+ terminal or to leave that terminal disconnected. This determines the direction the motor will

run. (See figure 3.)

I

used some parts from the Sherline thread cutting

attachment to get access to the lathe’s drive shaft.

The first thing to do is to install the

fixed shaft, sliding shaft and engagement lever from the Sherline

thread cutting attachment following the instructions for installing

the attachment.

This

installation involves taking the lathe apart – note do not take out the flat

head screw in the middle of the lathe bed at the tail end and only loosen the

one at the head end to put in the sliding and fixed shafts and pay attention to

the instructions about lining up the gap in the fixed shaft with the screw. Use the hex head screws in the blind holes at

each end of the bottom of the lathe base to release and reattach the lathe bed. I drilled holes in the plywood base to allow

access to the holes for the screws holding the lathe bed to the base.

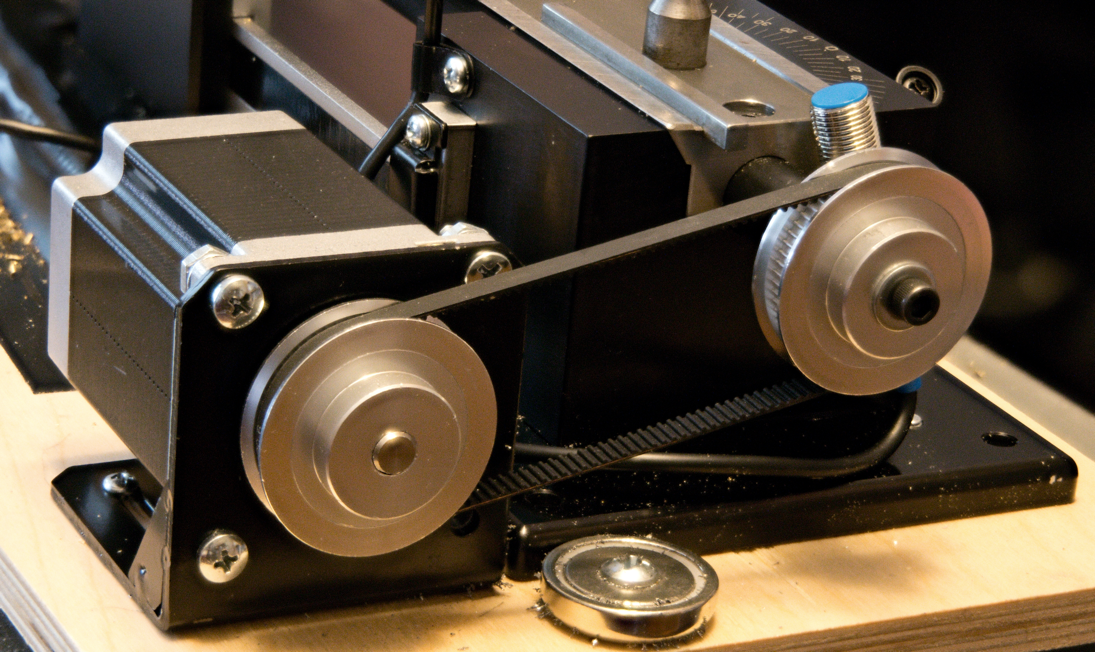

I

used 60 tooth, 5mm bore, timing pulleys designed for a

6mm timing belt for both the stepper motor and the fixed shaft extension of the

lead screw to provide a 1:1 ratio between stepper motor speed and lead screw

speed. I also used a 320 tooth 6mm timing belt to connect the stepper motor to

the drive shaft. You need to drill out the bore of one pulley to 8mm to match

the shaft on the stepper motor. Using a 3/8 end mill in the lathe or in a mill,

you need to cut a 3/8 dimeter shelf about 3/32 deep in the other pulley and,

using a 1/8” end mill, cut a lobe on one side of the 3/8 shelf. This is to fit

the end of the thread cutting attachment fixed shaft. (See figure 1.)

Figure 1: lead

screw pulley

Mount

the modified pulley on the end of the fixed shaft using a hex driver 10-32

bolt. You may need a flat washer on the

bolt to keep the bolt head from going into the hole in the pulley.

You

then need to figure out where to mount the stepper motor so that belt is just

tight enough. To do this, mount the stepper motor on the bracket. Mount the other

timing pully on the stepper motor. Put the timing belt on the pulleys and

position the steeper motor and bracket so the belt is straight &

tight. Trace an outline of the bracket

base on the plywood. Remove the pulley

from the motor and the motor from the bracket and, using the outline you just

made, position the bracket & screw it down to the plywood with #6 1/2"

round or pan head wood screws. Reinstall the stepper motor, pulley & timing

belt. (See figure 2.)

Figure 2: stepper

motor installed with belt and pulleys

I

cut a hole in the plywood just behind the stepper motor and ran the stepper

motor cable through the hole and under the plywood to the electronics box that

I placed at the back right of the plywood base so that the cable would not

become a chip trap.

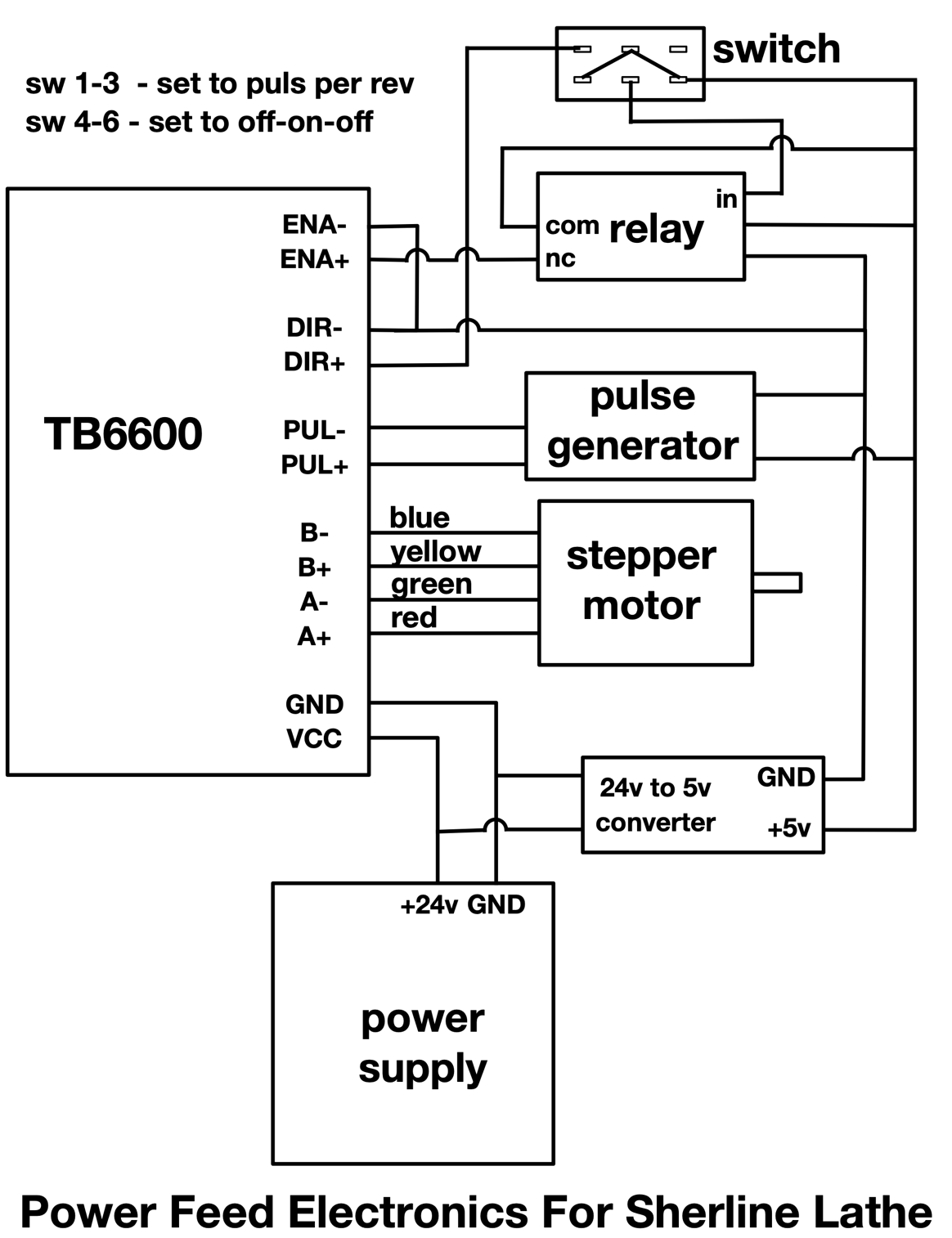

Assemble

the electronics (see figure 3) and connect the stepper motor to the

driver. Set switches 4-6 on the TB6600

to select 3 amp (off-on-off) current. Set switches 1-3 to the number of pulses you

want to have per revolution of the stepper motor shaft. I found that the number of steps did not make

a great difference in the actual top speed of the stepper motor – that seemed

to be determined by the stepper motor itself. I wound up using 800 pulses per

revolution (on-off-off).

Figure 3: diagram

of electronics for power feed

I

put the switch on the aluminum bracket that I mounted under the lathe bed

alongside of the pulse generator. (See

figure 6.)

Figure 6:

installed pulse generator and control switch

I

mounted the switch so that the action is horizontal. Pushing the switch to right causes the saddle

and crosslide to move to the right, and pushing the

switch to the left causes the saddle and crosslide to

move to the left. The pulse generator can be adjusted to set the speed that the

saddle moves. I used a momentary switch so that the moving saddle is less

likely to move out of control and cause damage.

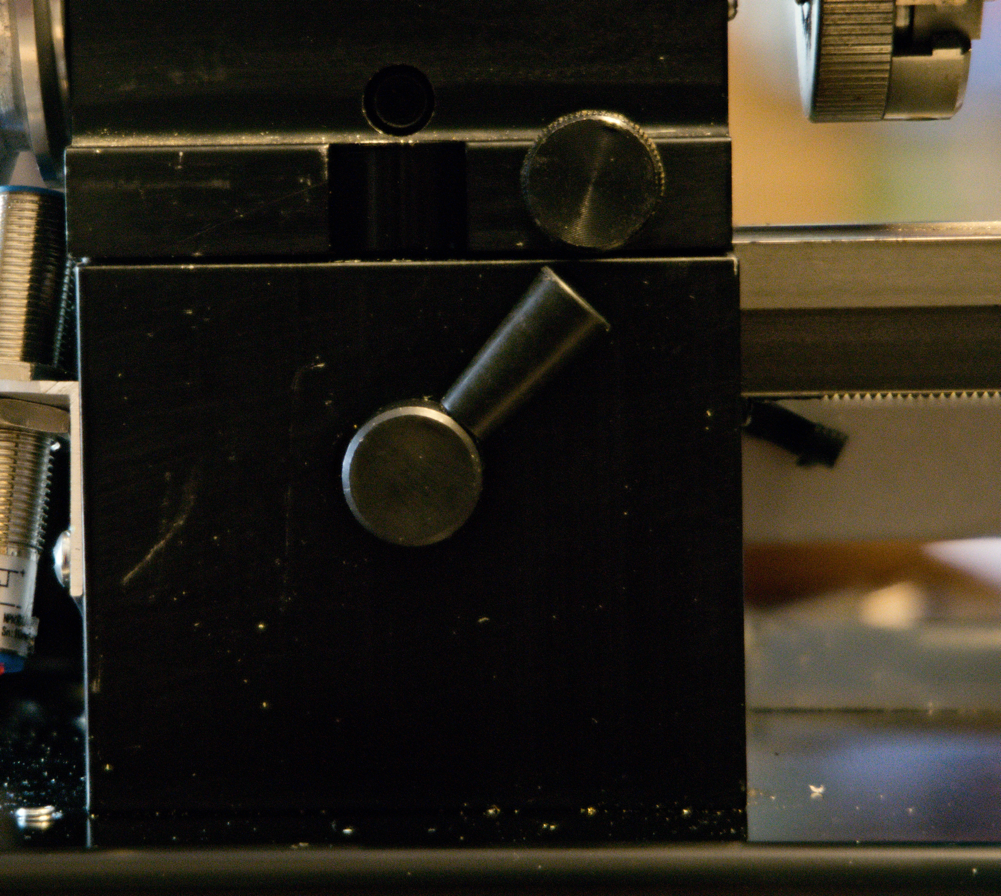

To

use the power feed, you rotate the engagement lever (see figure 8) clockwise while

manually turning the lead screw with the tailstock drive wheel until the flat

spot in the sliding shaft engages with the flat spot in drive shaft. Then you can

push the switch right or left to power feed the saddle and crosslide.

Figure 8:

engagement lever

Parts

list for power feed

The non-Sherline

links here point to Amazon but the same parts are available from many other

sources if you prefer to not deal with Amazon.

Sherline Fixed shaft - part

#15430

Sherline Sliding shaft - part

#15090

Sherline Engagement lever -

part #15420

Mounting bracket

for the stepper motor

timing pulleys (2)

– 60 tooth 5mm bore for 6 mm belt

Copyright

Ó 2024 Scott

Bradner

2024-09-05