2

Axes DRO for Sherline lathe

This

article assumes you have read Sherline Lathe

Infrastructure.

This

article describes how to install an inexpensive X-Y digital read out (DRO) on a

Sherline lathe with the machined base.

Sherline

does sell a DRO kit for its lathes (part no 8200) but their DRO is

quite expensive and does not actually tell you where the tool bit is and the

display is annoying because it only displays the X position or the Y position

not both at the same time. The kit does

include a tachometer but you can put a tachometer on the lathe for less than

$30. (See separate article.)

I

say that the Sherline DRO does not actually tell you where the tool is because

it depends on the rotations of the handwheels and does not account for backlash. This article describes a DRO which shows the

actual movements of the crossslide and of the saddle and thus shows the actual relative

location of the tool. In addition, it is

quite a bit cheaper than the Sherline unit.

There

are two different parts: the crosslide DRO (Y axes) and the saddle DRO. (X

axes)

The

Y axis DRO.

The

Y axis DRO is basically a 6-inch digital caliper with pieces cut off and

mounted on the crosslide. There are many

sources for this size caliper online. You

want to get one with a plastic body with the rest in stainless steel because

you will need to sand off parts of the body to get a good fit. Figure 3 shows the basic type of caliper you

should get. You can get the level of precision

that you want from 2 decimal places to 4 and, for more money, 5. Figure 1 shows

the modified caliper installed on the lathe.

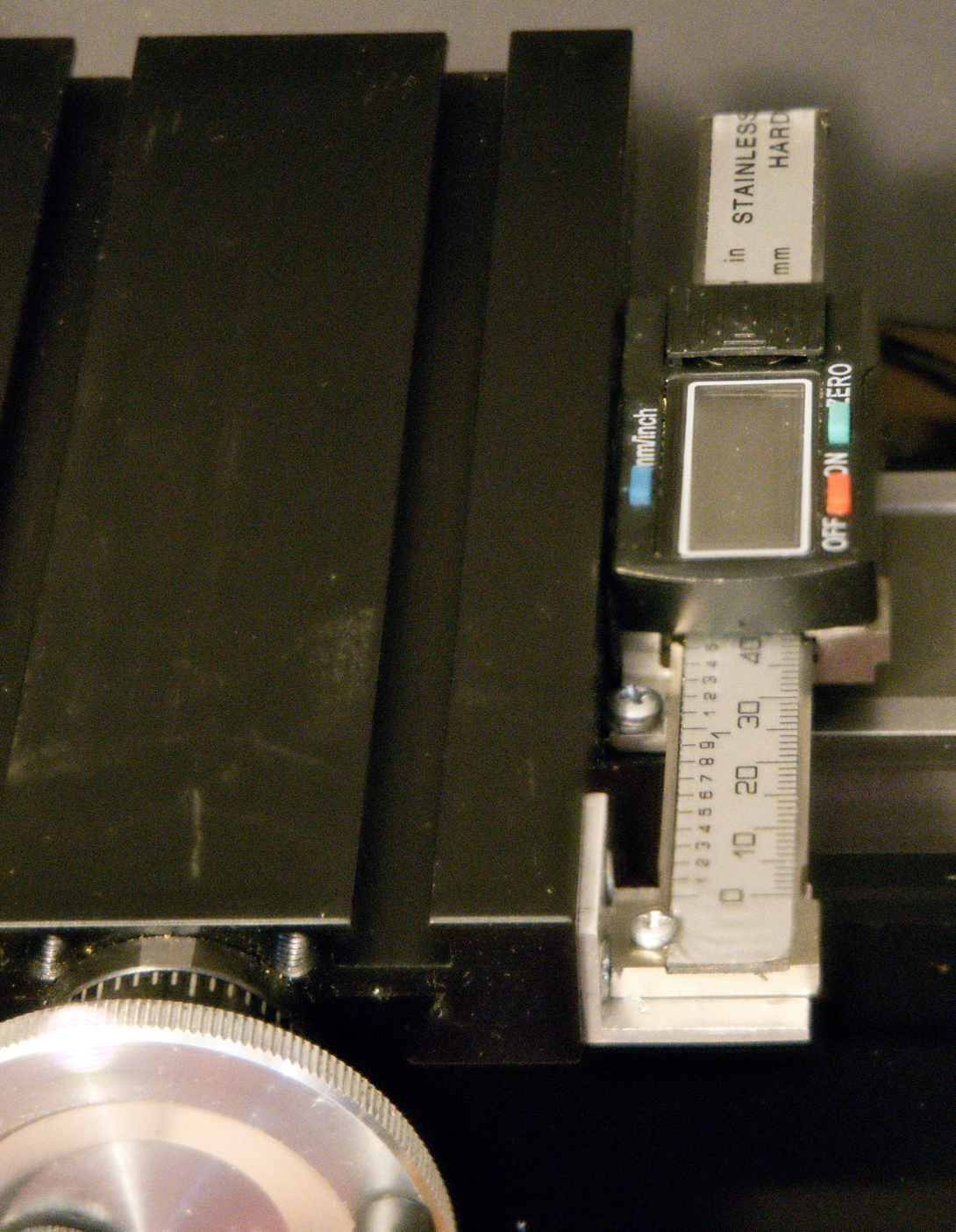

Figure 1:

Crosslide DRO

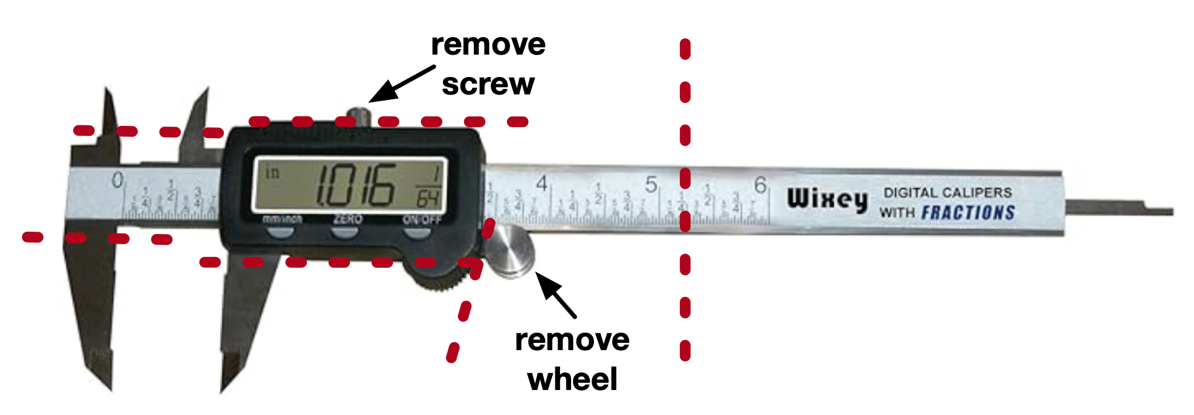

Figure

2 shows the cuts needed on a 6-inch digital caliper. The cuts can be made with a cutoff saw, or,

in the case of the plastic core, a sander.

Figure 2: cuts

needed to a digital caliper

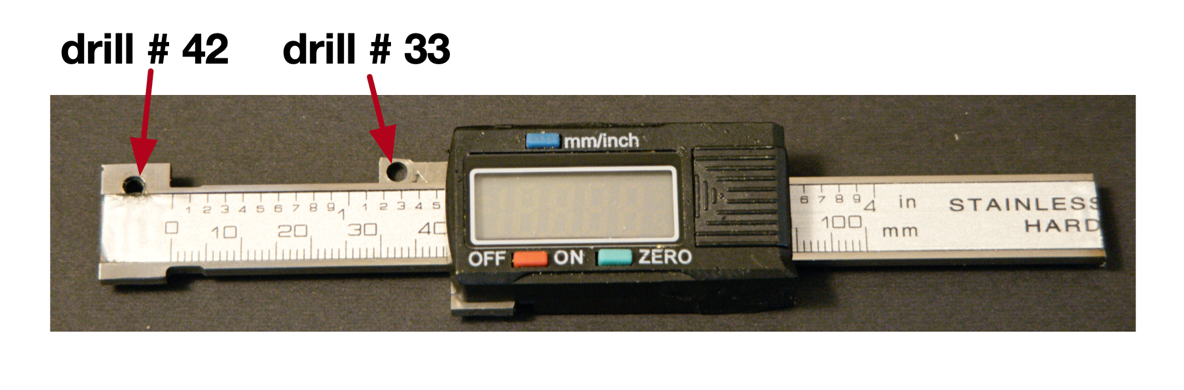

Figure

3 shows the result of the cuts and shows the two holes that need to be drilled.

Figure 3: digital

caliper after cuts

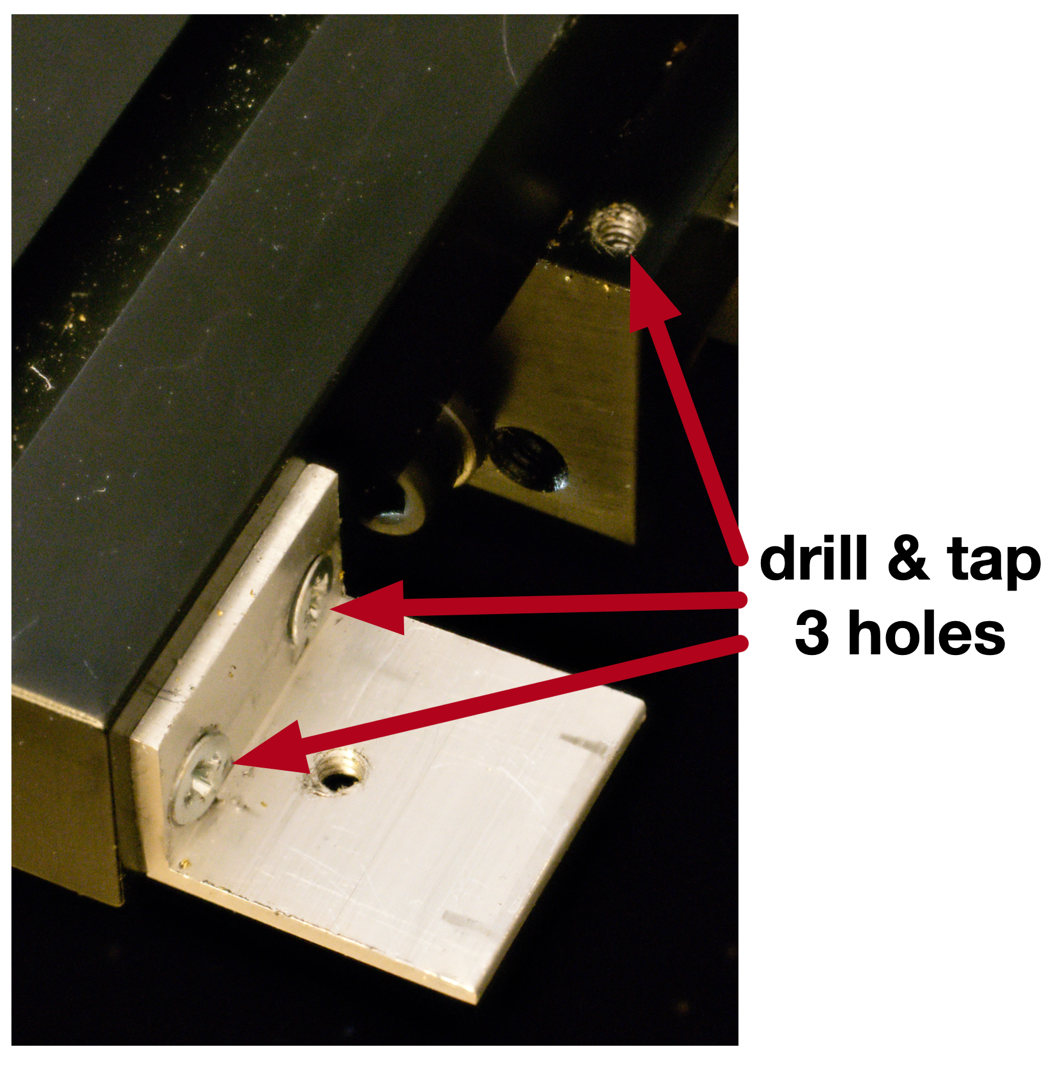

You

need to drill and tap the crossslide and saddle in three places 4-40 screws –

see figure 4.

Figure 4: drill

and tap locations

Figure

4 also shows the small aluminum bracket that is needed to support the end of

the caliper. The hole in the bracket is

a #42. The caliper is bolted down to the

saddle with a 3/26 long 4-40 screw with a lock washer and bolted to the bracket

with a 3/16 2-56 screw, lock washer and nut.

The top of the caliper should just clear the side of the crosslide. The result should be what is shown in figure

1.

The

body of the caliper is fixed to the saddle and the slide of the caliper is tied

to and moves with the crosslide and thus shows the position changes of the

crosslide.

X

axes DRO

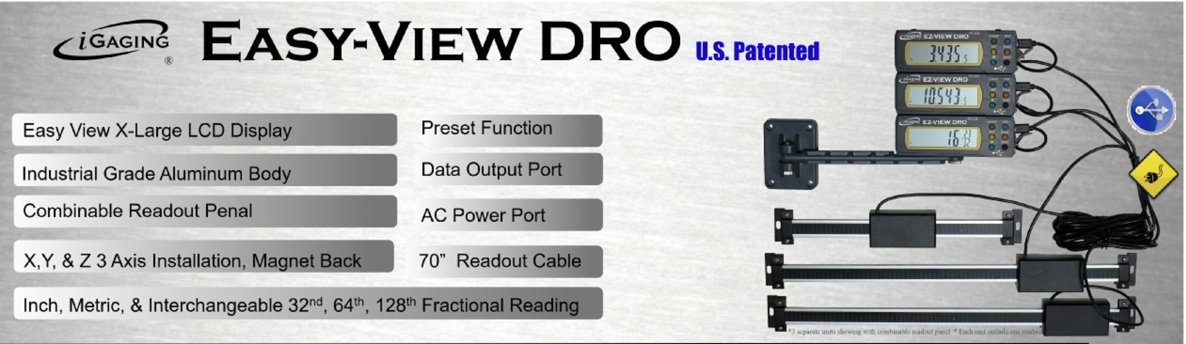

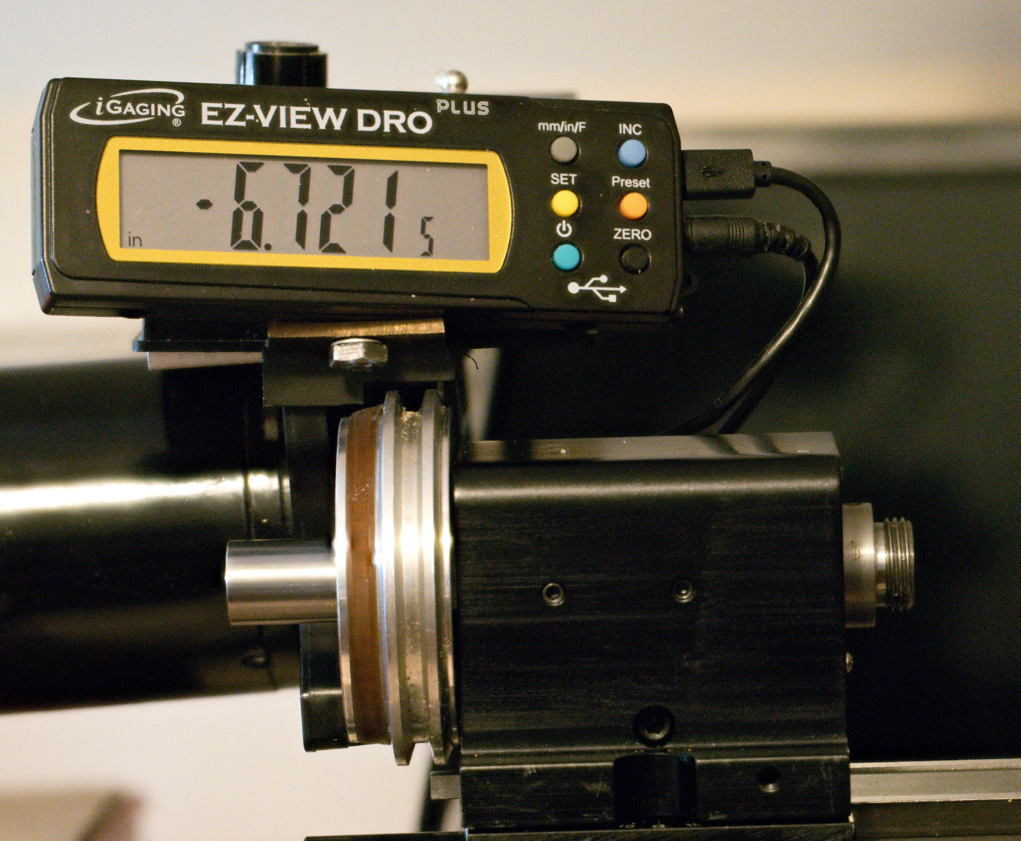

The

X axes DRO is not much more complex. It

is based on an iGaging Easy-View 24-inch DRO cut down to 20 ¾ inches with a

hack saw. There are many sources for

this online, with prices ranging from $42 to $179. See figure 5.

Figure 5:

Easy-View DRO label

The

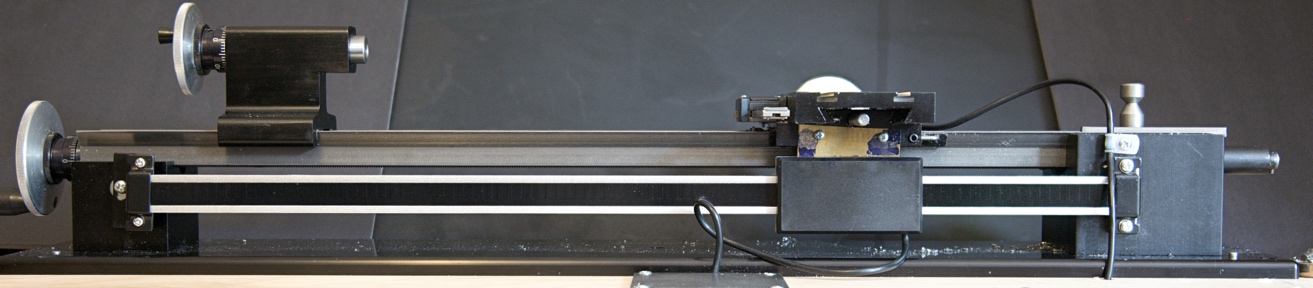

shortened iGaging bar is bolted to the back of the lathe base. See figure 6.

Figure 6: lathe

back view with DRO sensor & bar

The

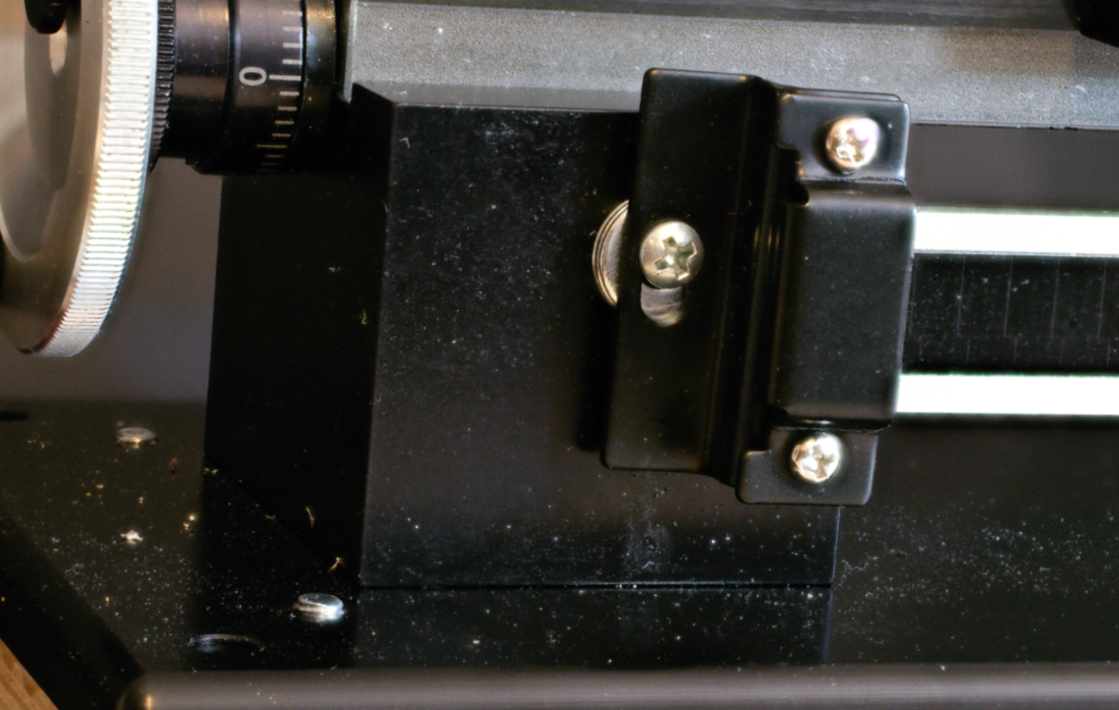

tailstock end of the measurement bar is bolted to the lathe base with a single

8-32 screw with some washers acting as a spacer to line up the bar with the

edge of the lathe bed. One 8-32 hole

needs to be drilled & tapped into the tailstock pillar on the lathe base.

See figure 7.

Figure 7: DRO bar

mount tail end

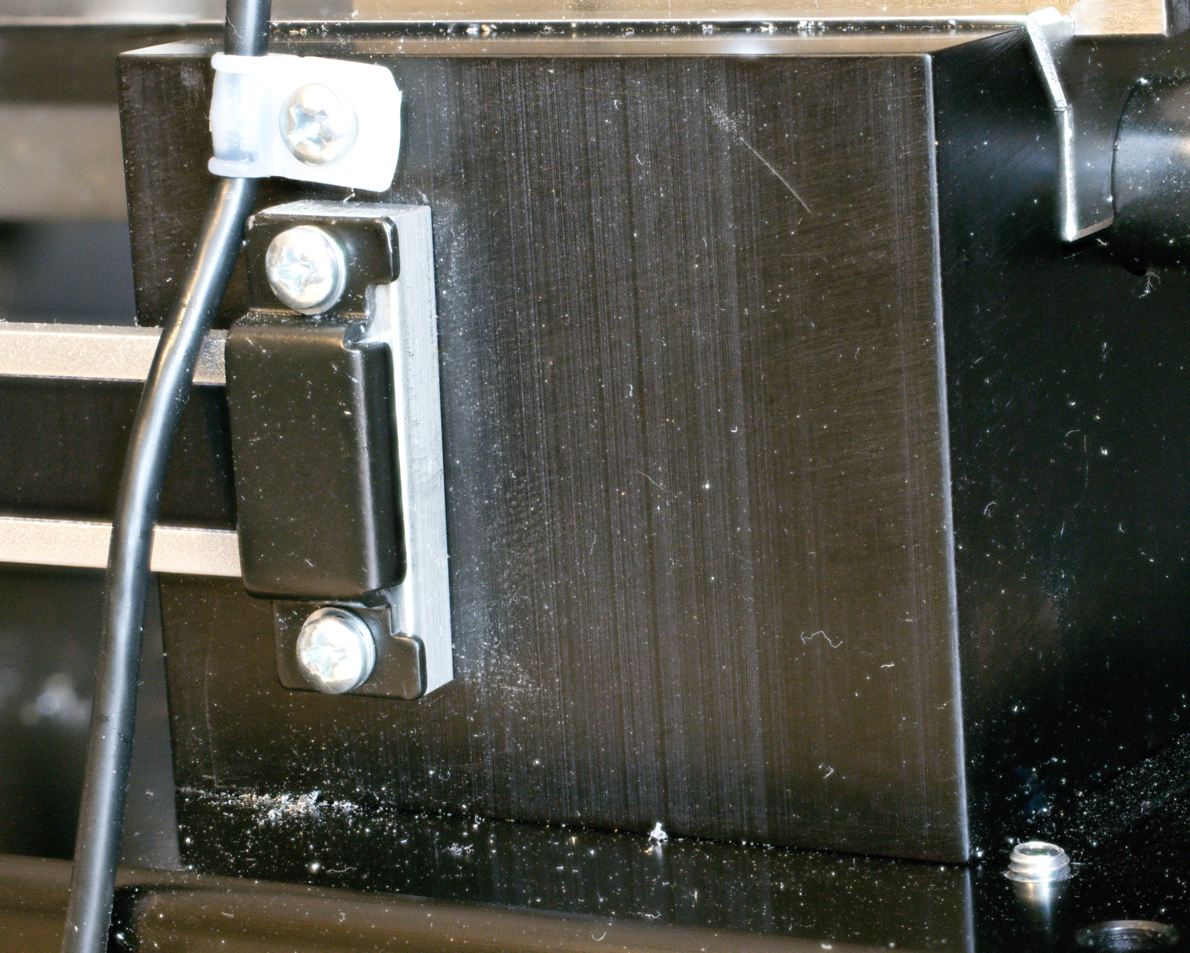

At

the headend the bar is fastened to the pillar with half of the bracket that

comes in the kit along with a small block of ¼ inch thick aluminum as a

spacer. Two 4-40 holes need to be

drilled and tapped to mount the bracket at this end. A third 4-40 drilled and tapped hole is used

for a cable clamp to hold the cable going from the slide sensor to the display.

See figure 8.

Figure 8: DRO bar

mount head end

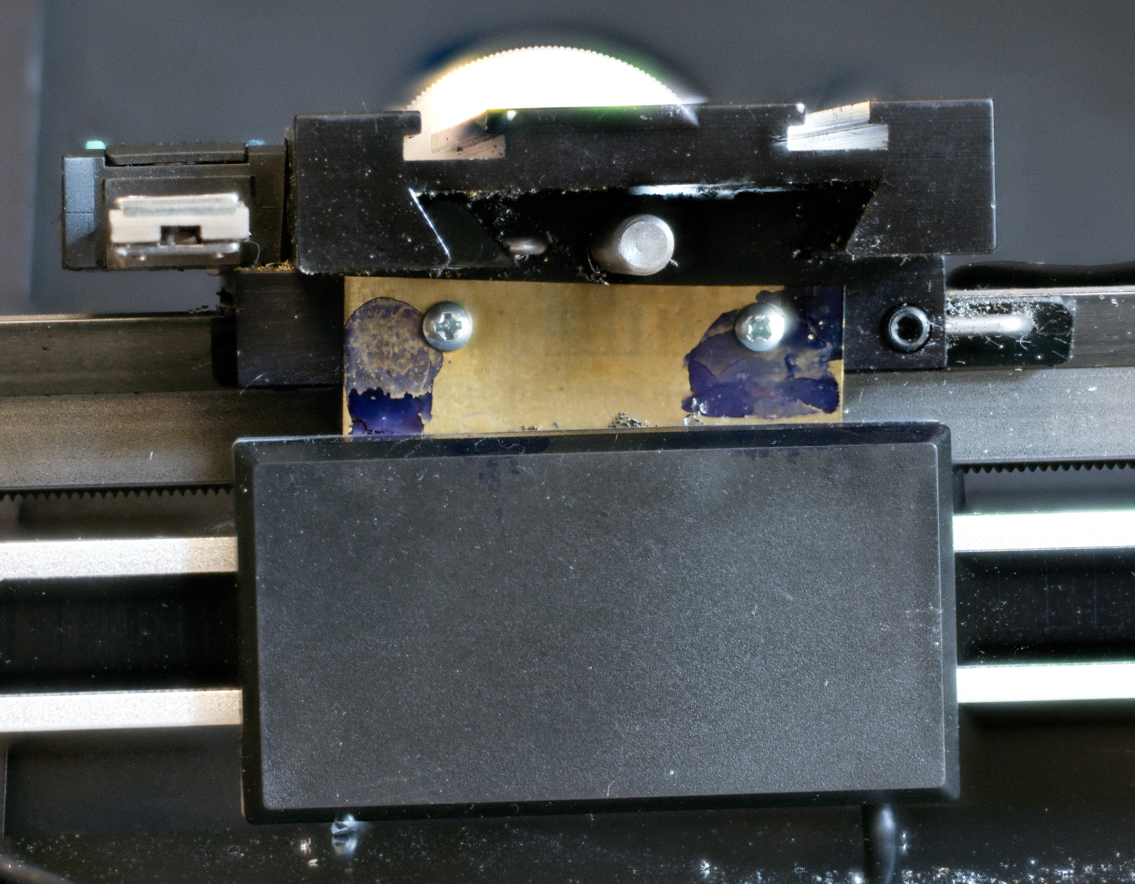

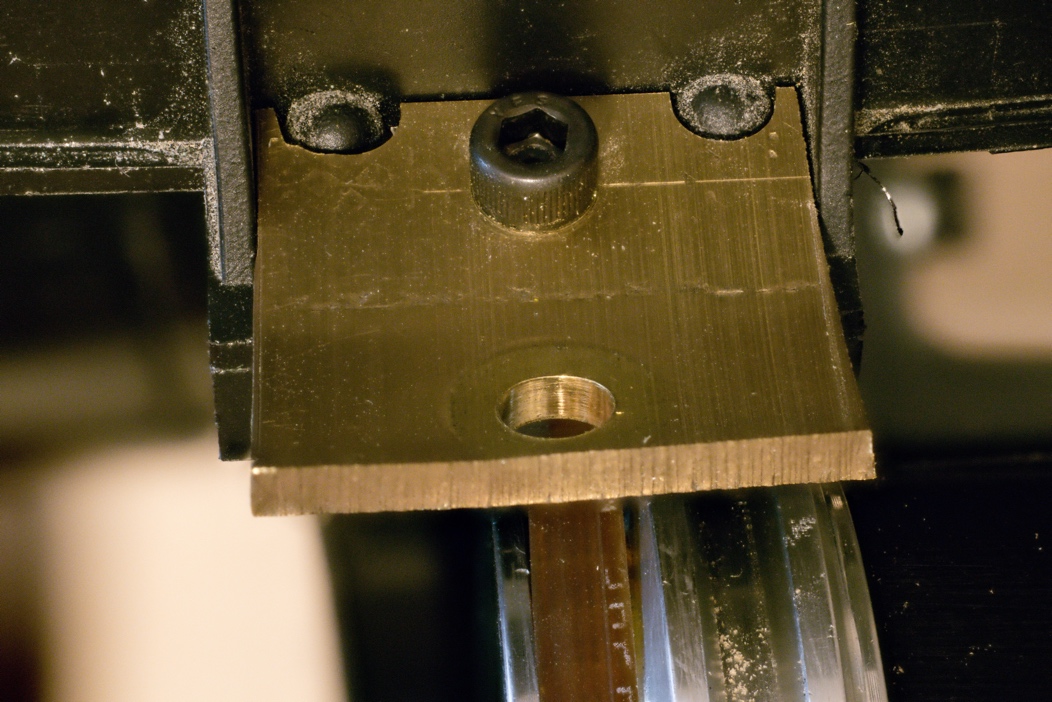

The

slide sensor is connected to the saddle with a small sheet of thin brass that

is bolted to the two 4-40 holes drilled and tapped into the saddle at the top

and to two pre-tapped holes in the back of the slide sensor. Figure 9 shows this from the back.

Figure 9:

connection between DRO sensor and saddle

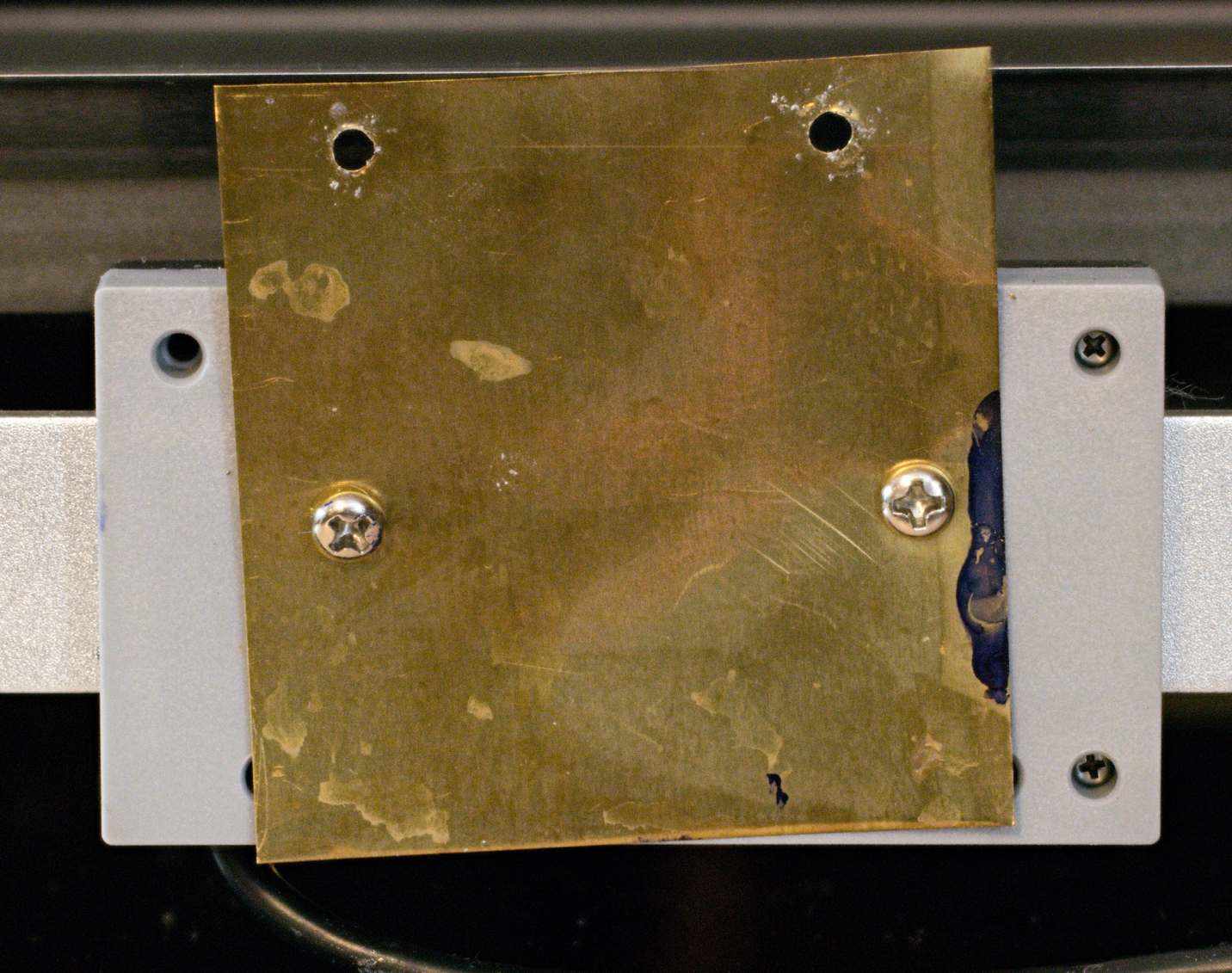

Figure

10 shows the sheet of brass mounted on the back of the slide sensor.

Figure 10: back of

DRO sensor showing brass sheet

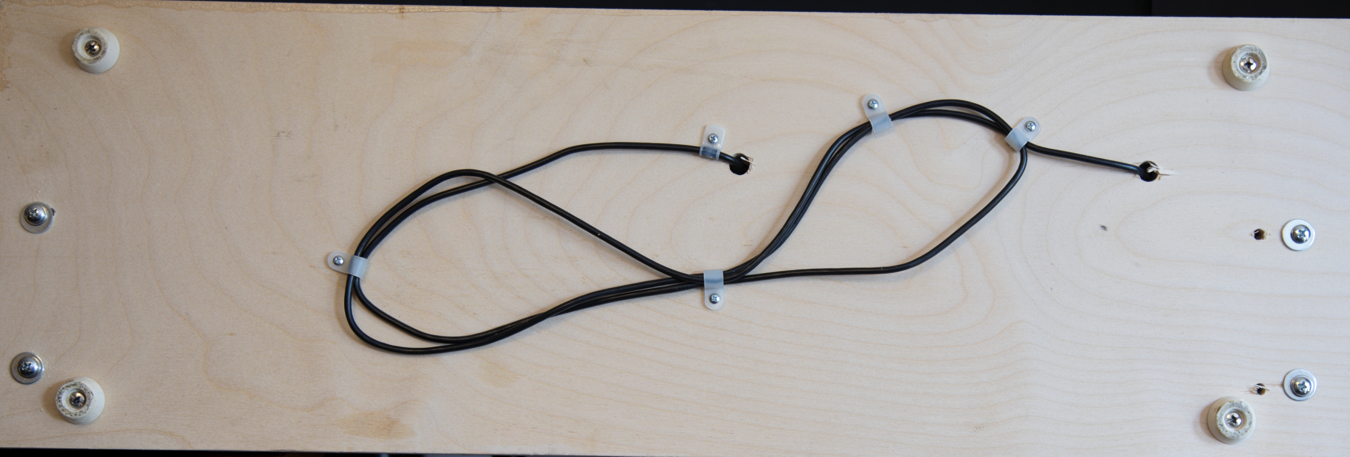

I

coiled the sensor cable under the lathe’s plywood base and secured it with

cable clamps. I drilled the hole for the

cable at the center point of the measurement bar and drilled the exit hole in

back of the head end of the lathe base. See figure 11. If you are also installing a lead screw power

feed or converting the lathe to use a stepper motor drive (see separate

articles) the end of the DRP cable can go through the hole that you make for

the stepper motor cables. (See figure 7 in the Hacks on a

Sherline Lathe

article.)

Figure 11: under

lathe plywood base

I

mounted the DRO display on a bracket I made connected to the control housing

for the lathe motor. See figure 12.

Figure 12: DRO

display on lathe with Sherline motor and control

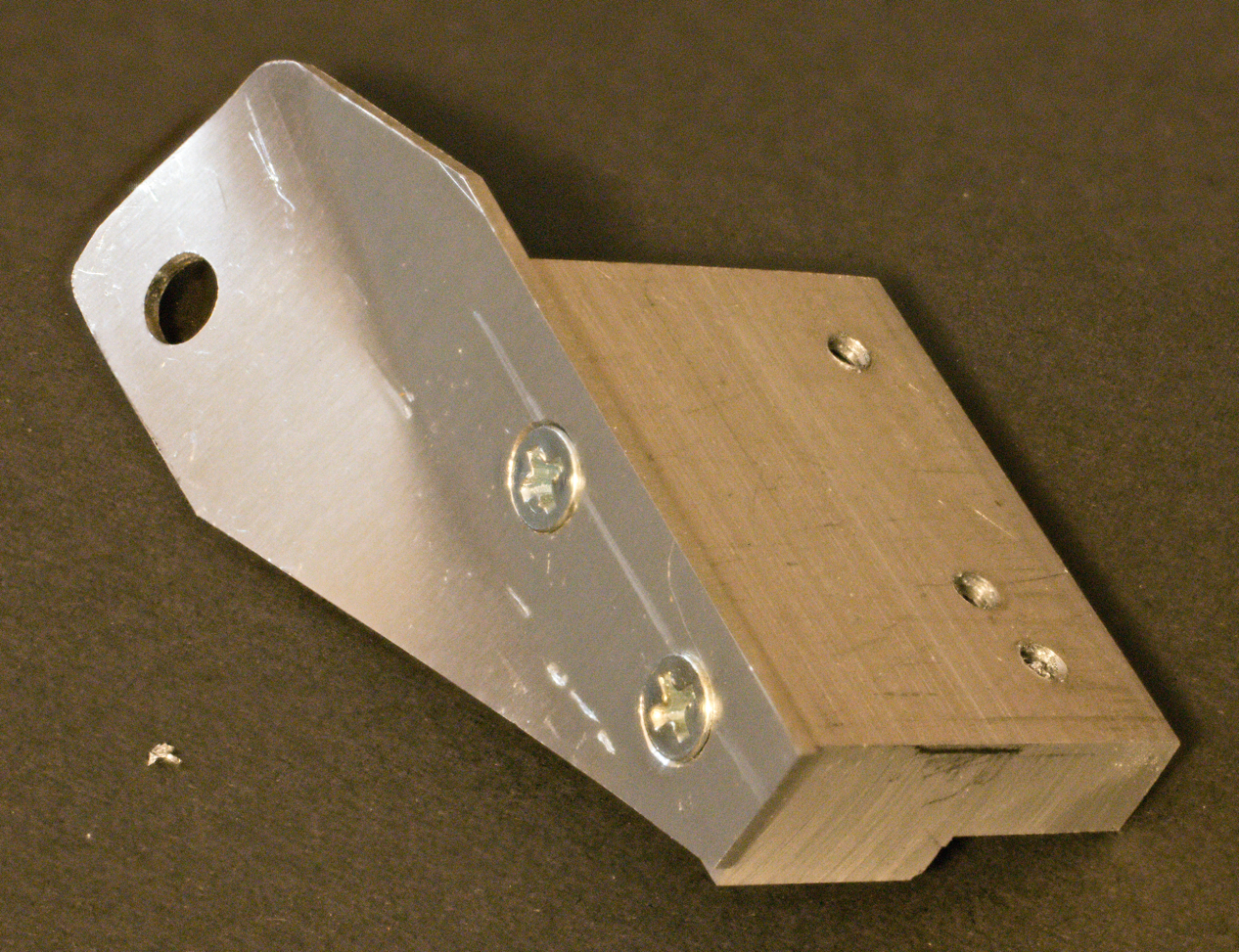

Figure

13 shows the bracket.

Figure 13: DRO

display bracket for lathe with Sherline motor and control

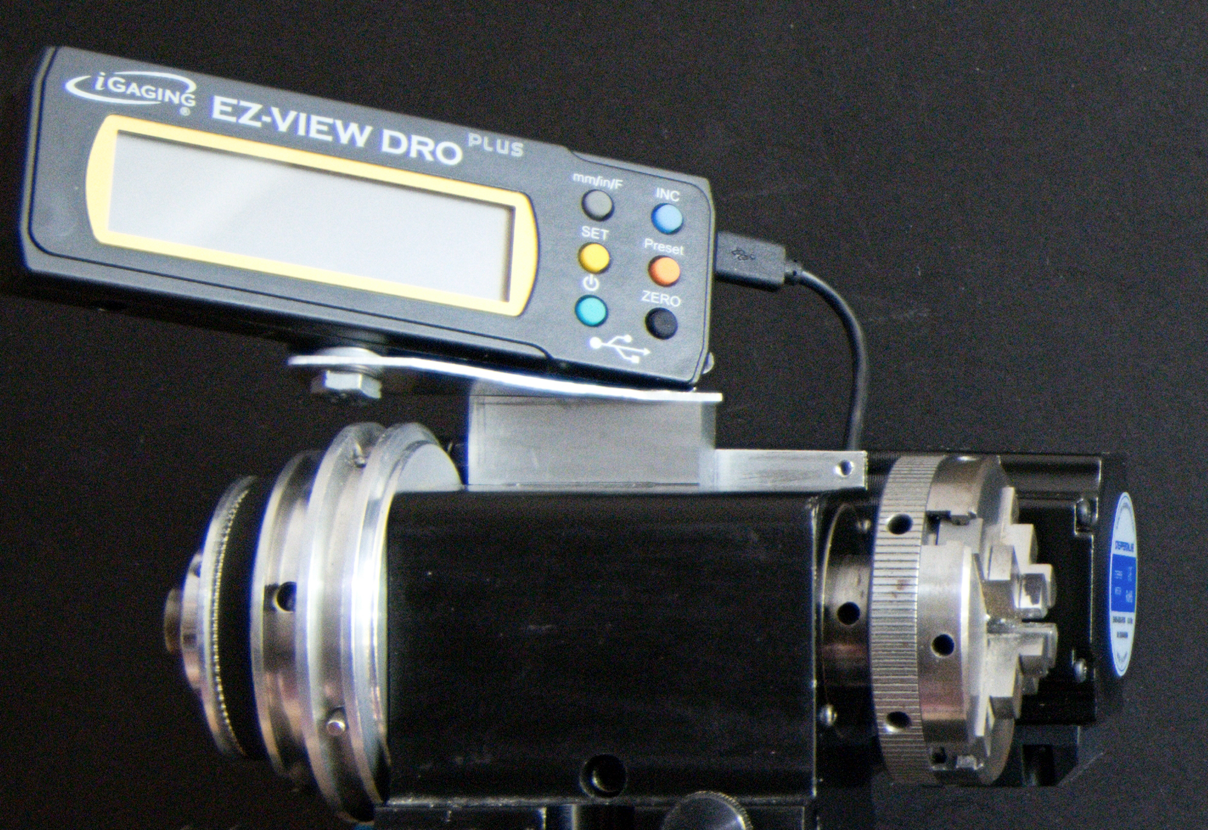

I

also made a bracket to mount the display on the stepper motor holder for my

lathe after I converted the lathe to use a stepper motor. (See separate article.) See figure 14.

Figure 14: bracket

for DRO display on Sherline lathe with stepper motor drive

Figure

15 shows the DRO display mounted on the spindle drive stepper motor bracket.

Figure 15: DRO

display on Sherline lathe with stepper motor drive

Parts

list

iGaging Easy-View 24-inch DRO

6 inch digital caliper

Copyright

Ó 2024 Scott

Bradner

2024-09-05