Toolpost Grinder for a Sherline Lathe

After

seeing them in action in various YouTube videos I decided to make a toolpost grinder for my Sherline

lathe. Sherline

sells a Micro Grinder Toolpost that is designed for a particular

high-speed grinder. But the Sherline post has the same problem that led me to develop

my own boring bar holder. The fact that

the post only has one tiedown bolt means that it will rotate if force is

applied to the end of the grinder. Any

rotation, even a small one, will cause the face of the grind stone to not be

parallel with the work which will affect the quality of the finish on the work.

The

holder I made for the grinder was based on the one I made for the boring bar

holder which has two tie down bolts which prevent it

from turning.

I

already had a dental drill setup that I used for close work on my models so I

wanted to use that. See figure 1.

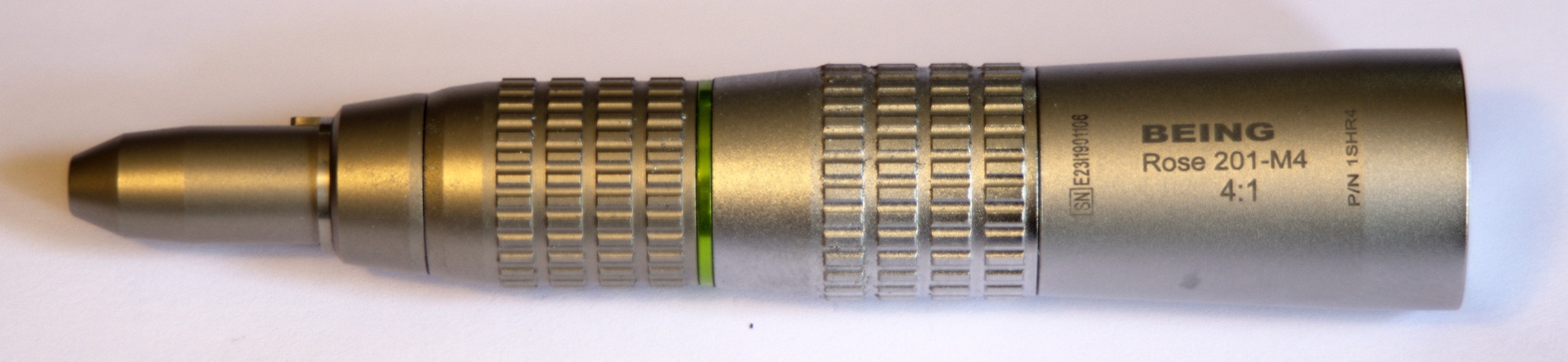

Figure 1: Dental

drill system

Figure

1 was taken from one of the many sites on eBay that sell the Marathon III

controller with a footswitch and mini-motor head. The motor is capable of 35K RPM according to

the adds. It does not have much power at

that kind of speed, nor is it very controllable, so I use speed reducing heads

with it. For example, I use a 64:1

reducing head (which I found on eBay) for drilling on a model and I use a 4:1

reducing head (also from eBay) with the tooolpost

grinder. See figure 2

Figure 2: 4:1

reducing head

This

reducing head is perfect for the toolpost grinder

application because it separates the clamping control for the tool (the left hand set of ribbed rings) and the fixed rings that can

be used for clamping (the right hand set of ribbed rings).

I

detailed the construction of the toolpost in my

article about making a boring bar holder.

Please go to that article to see how to make

it. The only difference is the size of

the hole. The hole in the grinder holder

was based on the particular grinding head I got. Figure 3 shows the toolpost.

Figure 3: toolpost for grinder

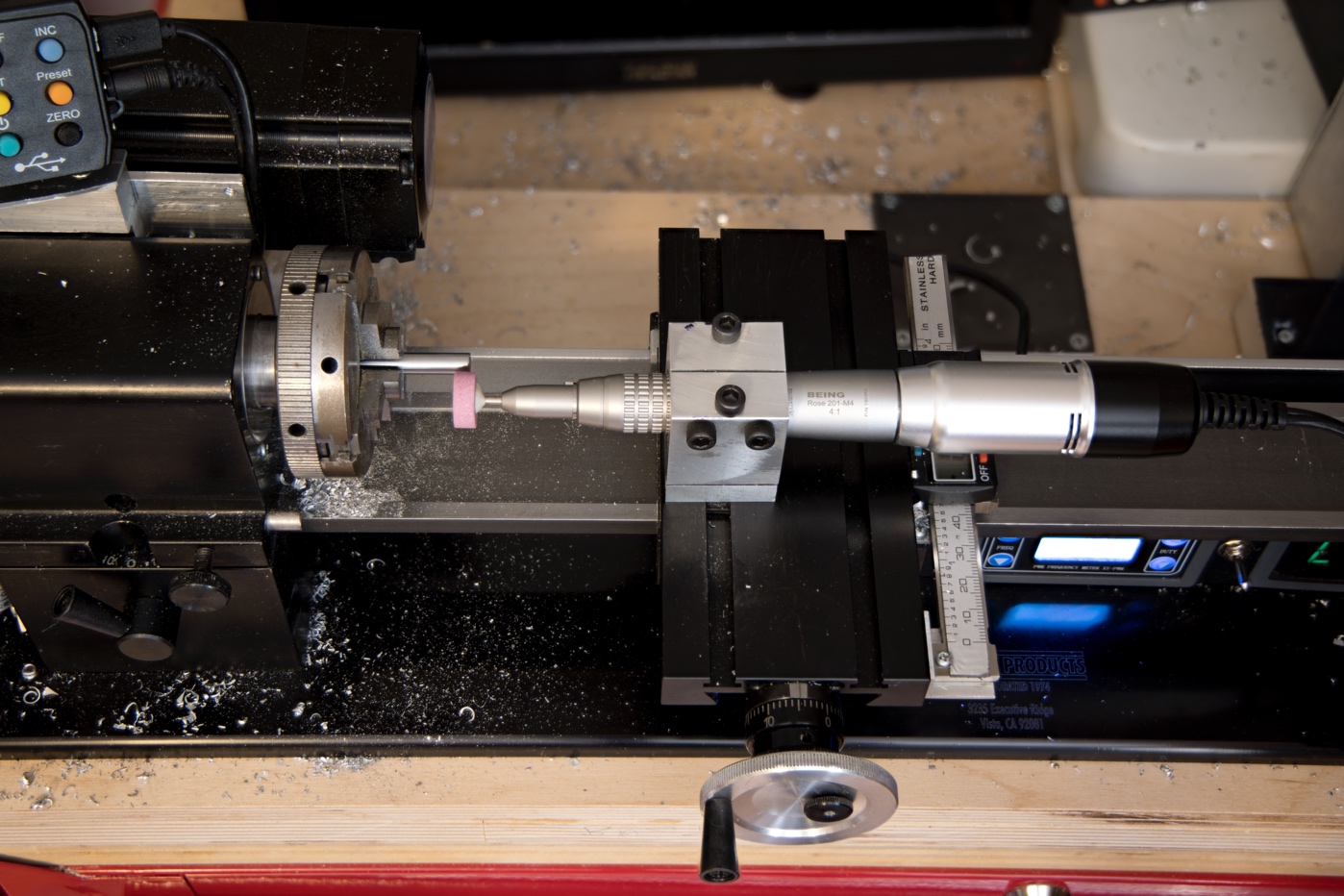

Figure

4 shows the grinder mounted on the lathe.

Figure 4: Toolpost grinder on lathe

Make

sure that the grinder is turning in the opposite direction of the lathe for

maximum grinding contact speed.

Copyright

Ó 2024 Scott

Bradner

2024-09-05