Tailstock

DRO for a Sherline Lathe.

I

decided that a tailstock DRO would be useful on my Sherline

Lathe. It turned out to quite easy to do

and quite cheap.

I

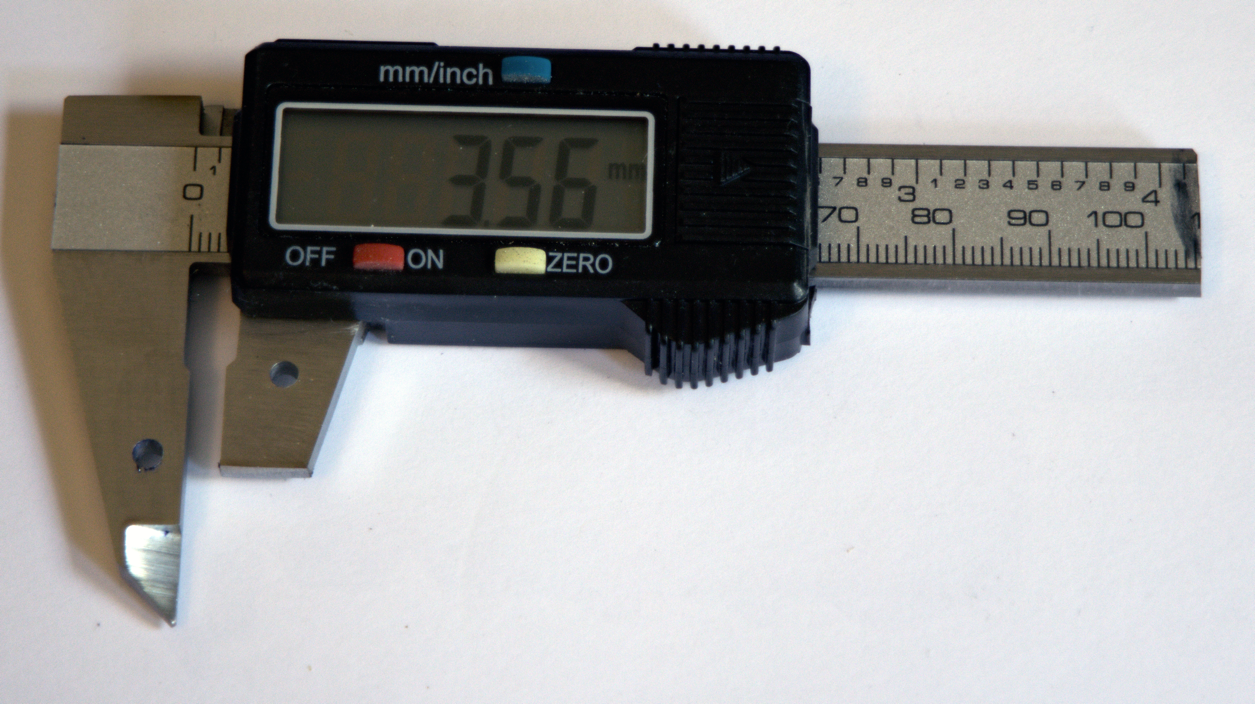

based the tailstock DRO on a 6-inch digital caliper. I made some cuts on the

caliper with a cutoff saw. See figure 1.

The two holes in the prongs are #33, which is the body brill for 4-40

screws.

Figure 1: modified

6-inch digital caliper

I

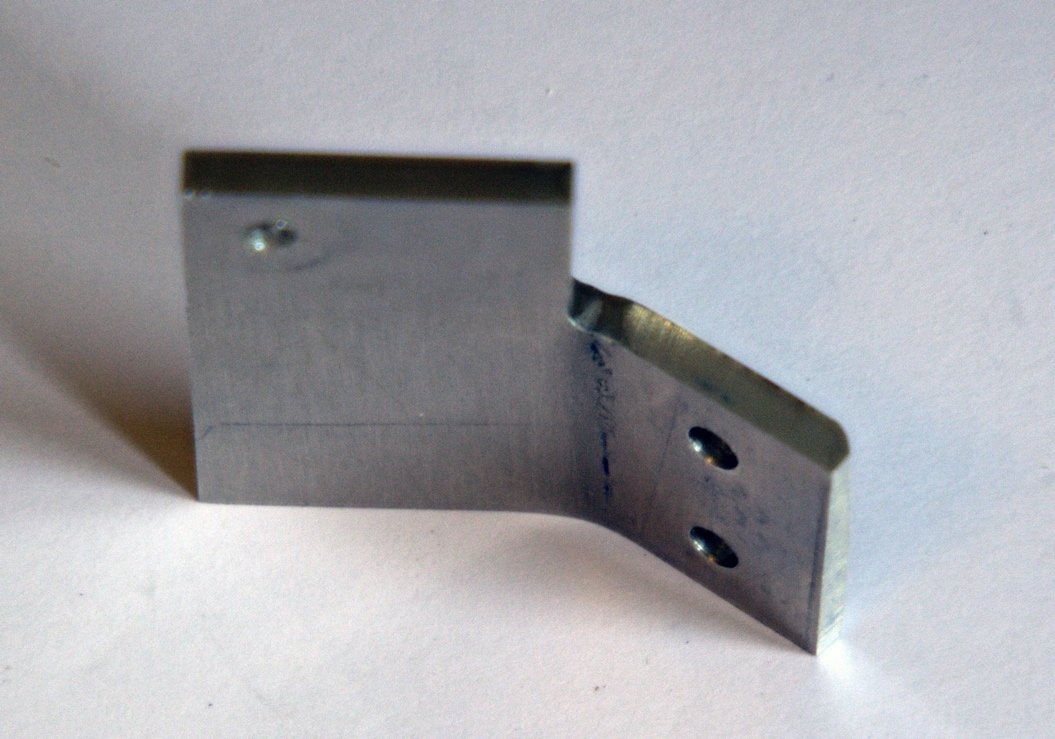

then made a small bracket to mount the caliper on the tailstock. See figure 2.

Figure 2: bracket

I

made the bracket out of 3/32 aluminum sheet but 1/16 would work just as well

since the bracket is not the subject to much stress. The part of the bracket on the right with two

holes will get bolted to the back of the Sherline

headstock. The holes are #28 which is

the body drill for 6-32 screws. The hole on the left part is #33, which is the

body drill for a 4-40 screw. A 4-40

screw will pass through this hole and through a #33 hole in the right prong on

the caliper shown in figure 1. The

angle of the bend is to let the caliper lay back so it is easier to see, you

should pick an angle that works for you.

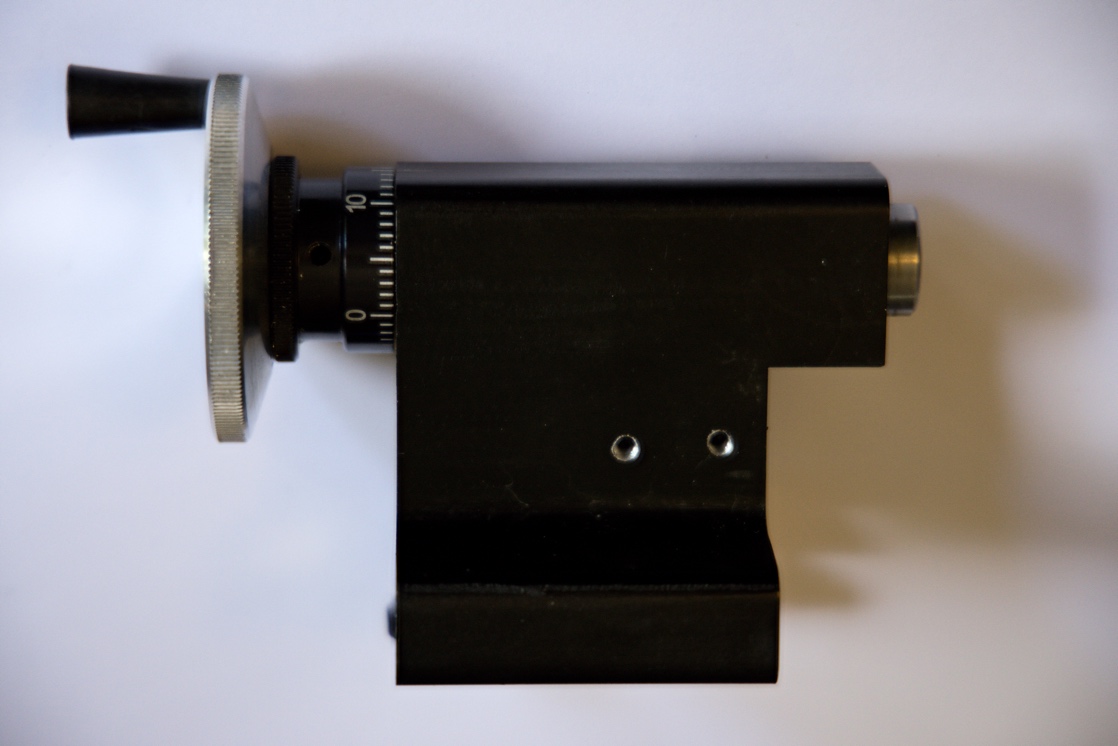

I

then drilled and tapped two 6-32 holes in the back of the Sherline

tailstock. See figure 3.

Figure

3: Sherline tailstock with tapped holes for bracket.

The

DRO works by fixing the body of the caliper to the tailstock and fixing the

slider of the caliper to the front of the tailstock’s spindle. The front ¼ of an inch of the spindle can be

used for a bracket since it does not not interfere with the function which

ejects things that have been put into the MT0 taper in the spindle.

I

first mounted the bracket to the tailstock with two 3/8” 6-32 round head screws

with lock washers. I then manually lined

up the fixed caliper prong with the bracket to figure out where to drill a hole

in the bracket and a matching one in the prong.

After drilling the holes, I bolted the caliper to the bracket with a

3/8” long 6-32 round head screw, lock washer and nut. I used a single screw to

hold the caliper to the bracket so that the system would have some flexibility

if the position of the caliper was a little bit off.

I

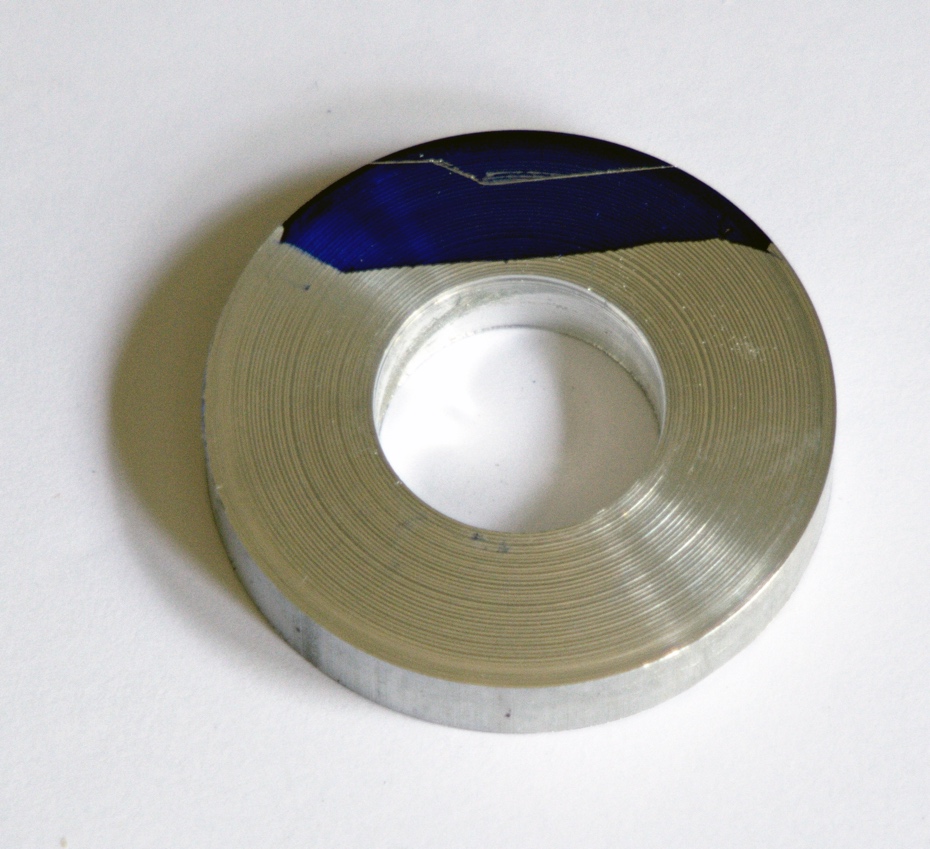

made a ¼” thick disk out of a piece of 1 ¼” diameter aluminum bar that I had

around. The disk has a hole in the

center that fits tightly over the tailstock spindle. I put the disk onto the tailstock spindle and

put some layout fluid on the disk so that lines would show up. I then scribed the side of the caliper’s

sliding prong so that I would know where to shape the disk so that the prong

would fit against it. See figure 4.

Figure 4: disk

marked showing the edge of the caliper prong

I

cut off the side of the disk with a band saw & a disk sander. I then mounted the disk on the tailstock and

lined up the caliper prong to figure out where best to put the hole for

fastening the prong to the disk. After

figuring that out and drilling a #33 hole in the prong I reinstalled the

caliper and used the hole to mark where the matching hole needed to be drilled in

the disk and then drilled and tapped the disk.

I

then drilled and tapped a 4-40 hole for a set screw to hold the disk to the

tailstock spindle. The hole for the set

screw is positioned so that the set screw goes into the slot in the tailstock

spindle. Then I shaped the disk with the

band saw and sander to make it look better.

I

put the disk back on the tailstock spindle and bolted the sliding prong onto

the disk using a 3/8” 4-40 screw and lock washer. Then I screwed a 4-40 set screw into its hole

to secure the disk to the spindle. Then

I put the tailstock back on the lathe.

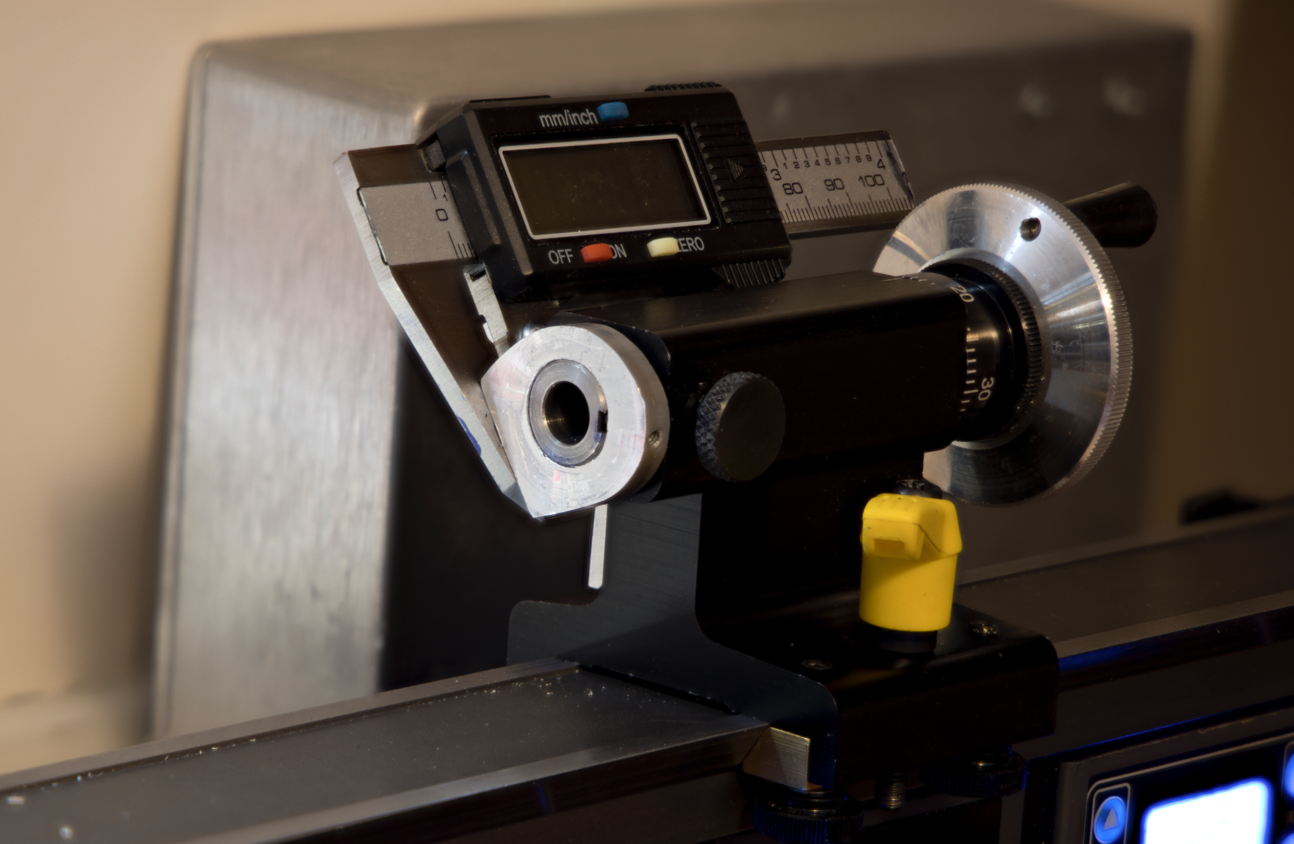

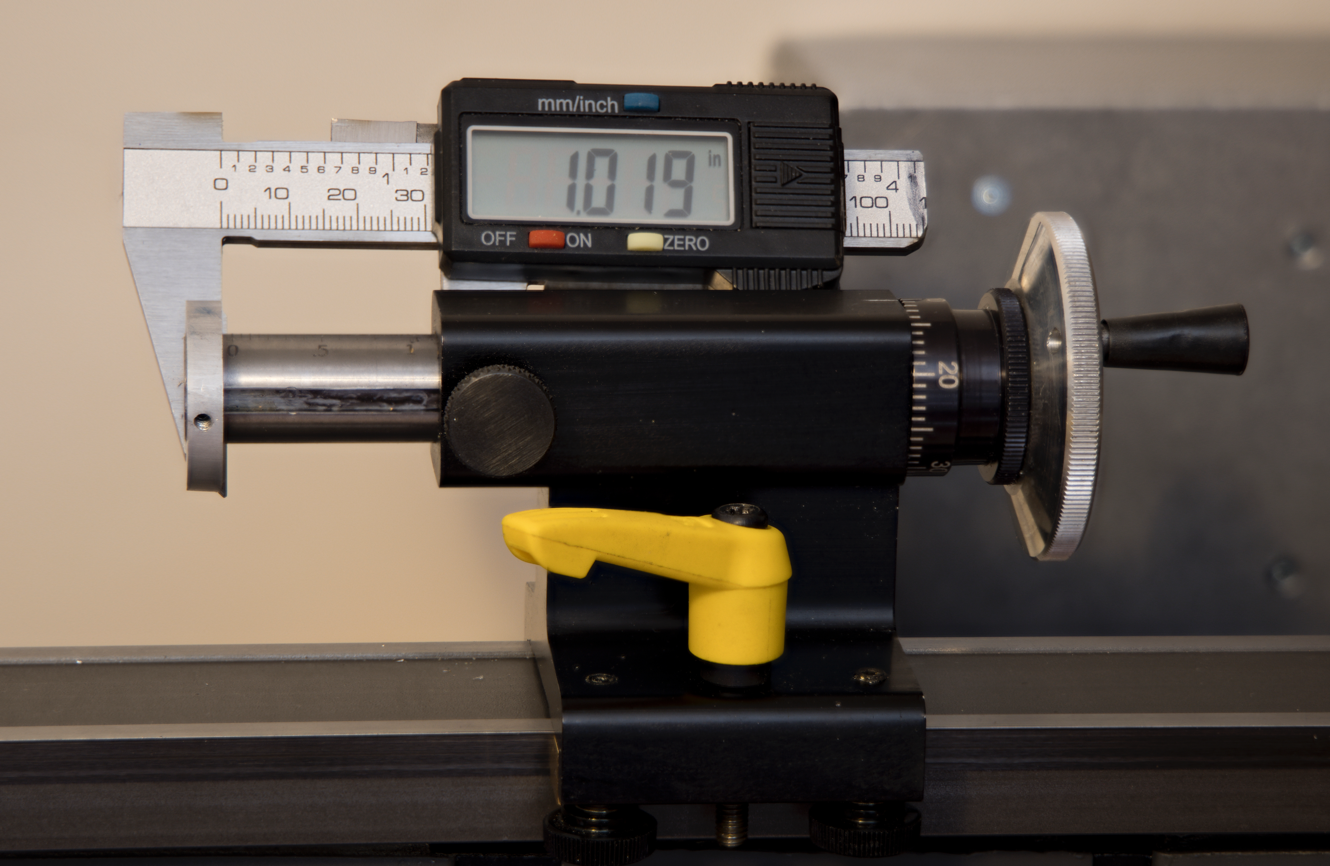

Figure

5 shows whole thing put together and mounted on the lathe.

Figure 5:

Tailstock DRO mounted on the lathe showing the shaped disk

Figure

6 is another view of the DRO.

Figure 6: DRO

mounted on lathe

Copyright

Ó 2024 Scott

Bradner

2024-09-05