Stepper

motor drive for Sherline lathe

This

article assumes you have read Sherline Lathe

Infrastructure

I

upgraded my old 8-inch Sherline lathe to a 17-inch version. The new lathe,

obviously, was wider than the old one.

The increased width made worse by the fact that the lathe’s motor sticks

out to the left a long way. In my case,

I am using a roll around tool box as a base for the lathe, the lathe itself

fits the base just fine but the motor stuck out to the left 6 inches and got in

the way of a Sherline mill on another tool box to the left.

I

thought that there might be an option to use a stepper motor that would not

stick out as much. I looked at

Sherline’s stepper motor

mount options.

It looks quite kludgy and not all that strong.

It also only accommodates a rather small stepper motor and says the max

RPM is 225. I thought I could do better

than that. The system described in this

article uses a much bigger motor and can go over 2,000 RPM if you are careful.

I

decided to use a closed-loop stepper motor and control because I found that the

open loop systems tended to stall when being started at higher speeds and I

found far less of that issue with closed loop systems. I decided to use a NEMA 23 sized motor since

it closely matched the size of the Sherline headstock and I decided to use the

424 oz.in motor to ensure that I had plenty of power. (See parts list at the end of this article.)

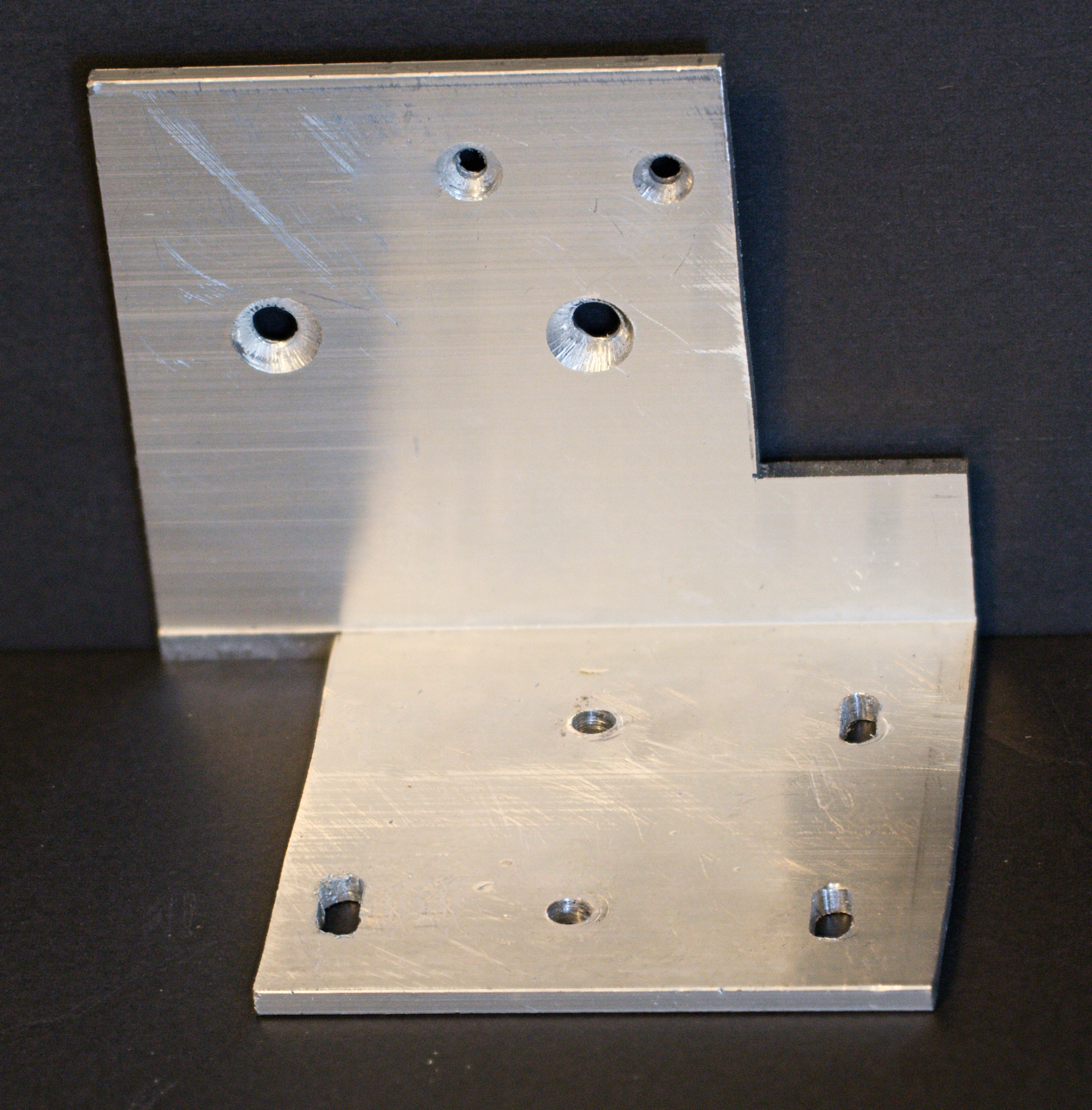

I

first made an aluminum bracket to hold the stepper motor to the Sherline

headstock. See Figure 1.

Figure 1: stepper

motor bracket

The Bracket is made from a 3 ¾ inch long

piece of 3 inch by 3 inch by 1/8 inch aluminum angle. You can also use the ¼ inch thick angle which

seems to be easier to get. The bracket

is bolted to the holes in the side of the Sherline headstock with 8-32 flat

head screws through the two countersink holes on the vertical part of the

bracket. The location of the holes is

such that the bottom of the angle lines up with the bottom of the headstock so

as to not interfere with the lathe base.

The two holes at the top of the vertical part of the bracket are to hold

a bracket for a DRO display. (See separate article.) If you are not going to install the DRO you

can cut the bracket off above the two mounting holes

The 3 slots in the horizontal part of the

bracket are to hold a piece of ¼ inch aluminum on which the stepper motor

bracket is mounted. They are slots to provide some amount of adjustment to

tighten the drive belt. There are three

because I could not figure out how to make a fourth because I could not get the

milling head in the right place to make it.

(I used a Sherline mill to make the slots.) The other two holes were

used to mount a block of aluminum that I used to hold the bracket when I was

milling the slots.

The length of the horizontal part of

the bracket was determined by the length of the bracket for the stepper motor.

The cutout on the right side of the vertical part of the bracket is to clear

the pulleys on the Sherline headstock.

I

used two 80 tooth, 8mm bore, timing pulleys and a 320 tooth 6mm wide timing

belt. You heed to bore out one of the timing pulleys to a bit more than 9/32 to

fit on the headstock spindle.

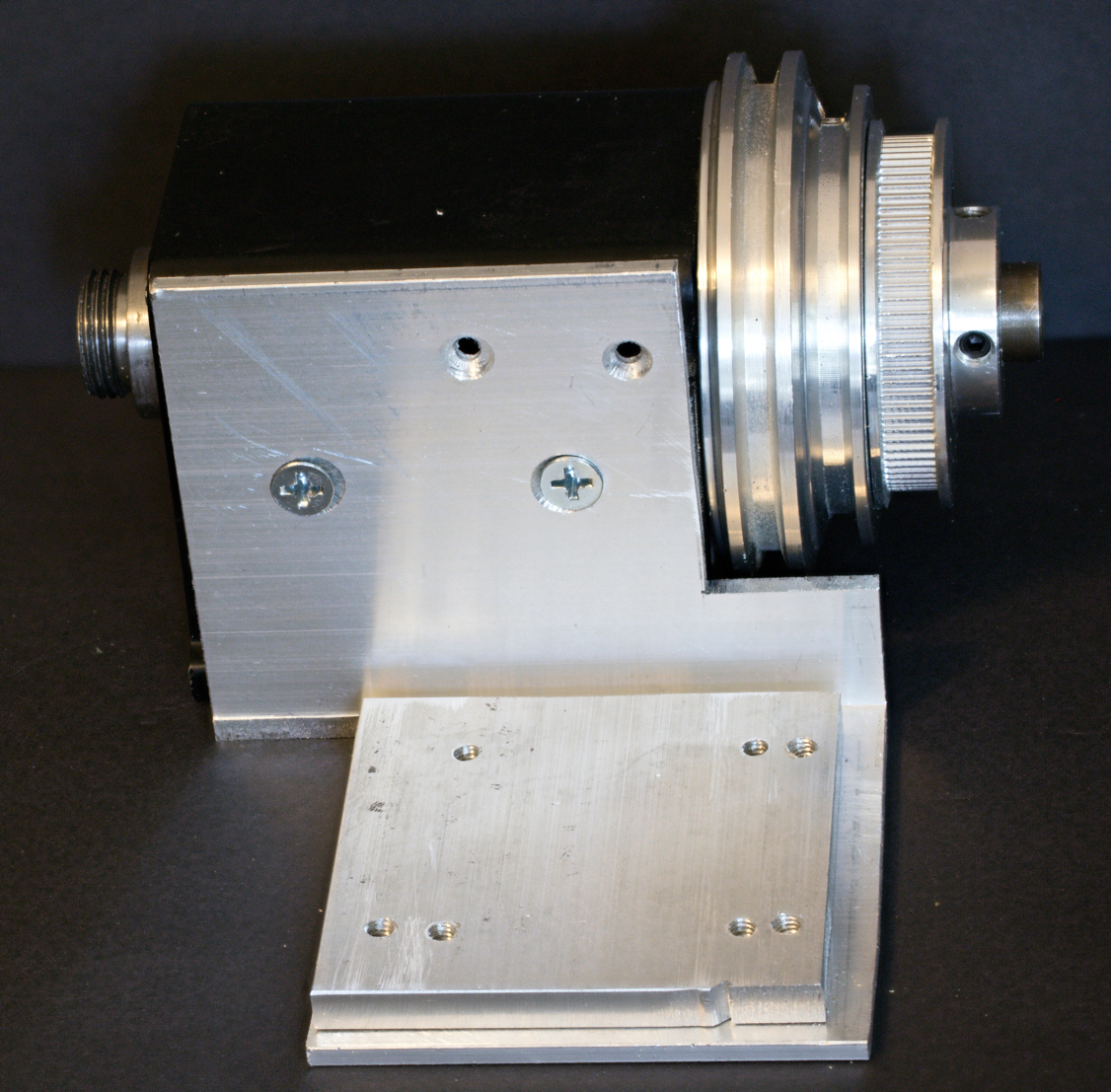

Figure

2 shows the bracket mounted on the headstock.

It also shows the ¼ inch aluminum piece that the motor bracket is bolted

to and can be slid back and forth using the slots milled into the bracket.

Finally, Figure 2 also shows the timing pulley mounted on the headstock

spindle.

Figure 2: stepper

motor bracket bolted to headstock

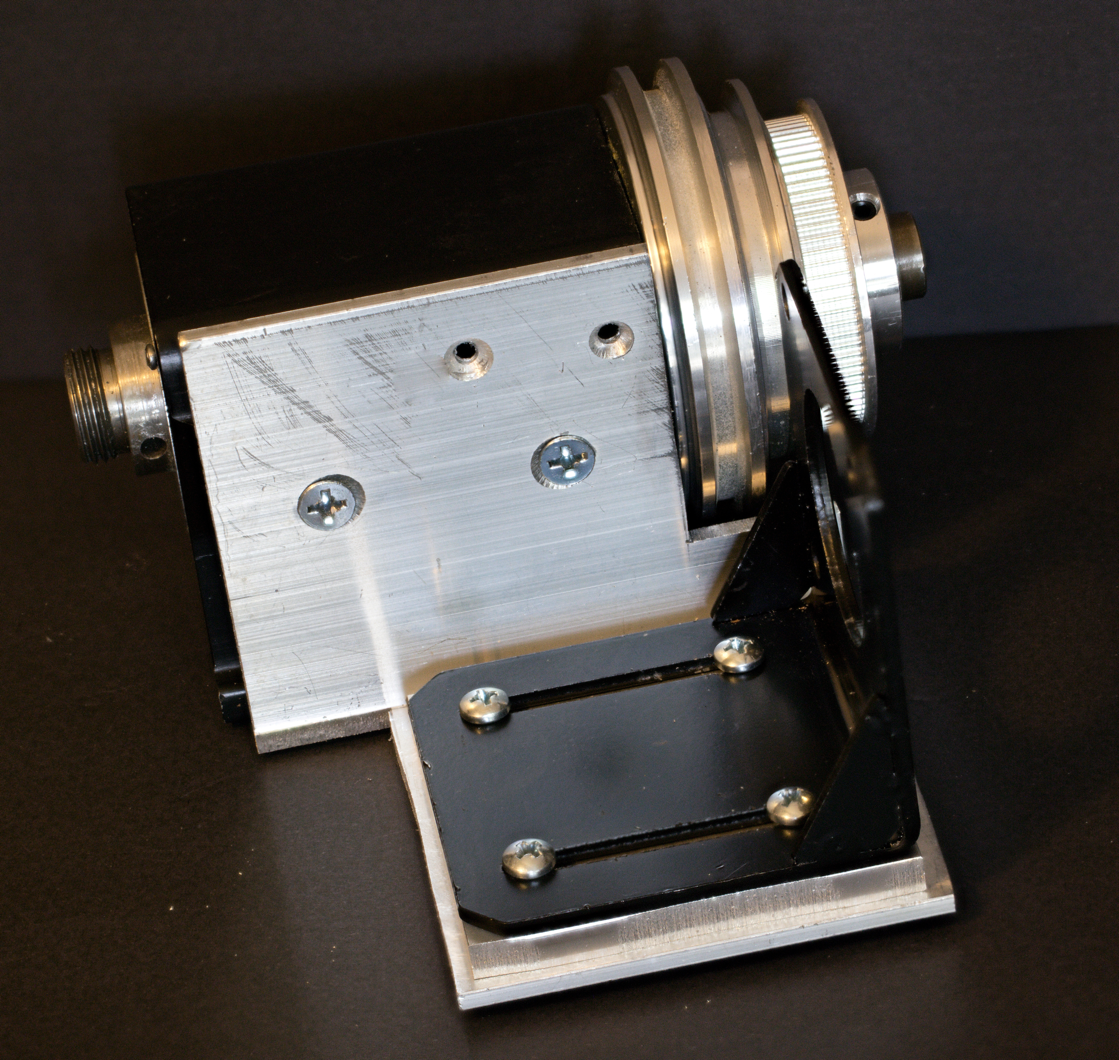

Figure

3 shows Figure 2 with the addition of the steel stepper motor bracket.

Figure 3: stepper

motor bracket with steel motor bracket

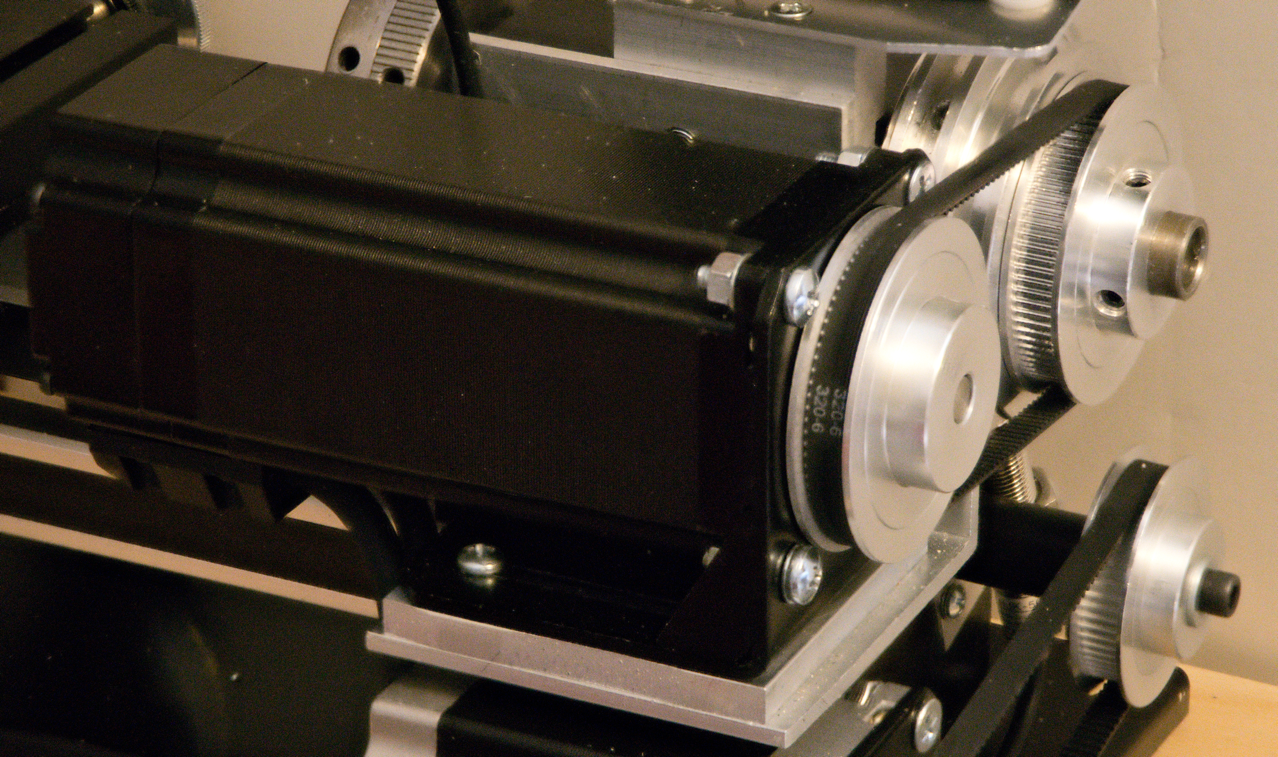

Figure

4 shows the full assembly with the stepper motor, the timing pulleys on the

stepper motor and the spindle as well as the timing belt and with the assembly mounted

on the lathe. Note the flathead screw in

the upper right corner of the stepper motor to provide clearance for the timing

belt.

X

X

Figure 4: stepper

motor installed on lathe

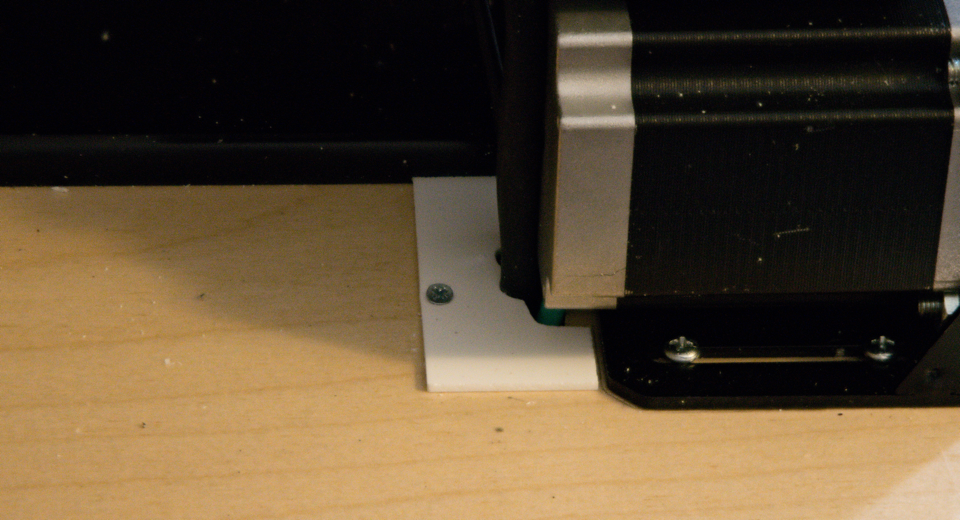

I

cut a hole in the plywood base so I could run the stepper motor cables under

the plywood so they would not trap chips from the lathe. I also screwed a small piece of 2mm thick

styrene that had one edge shaped to the profile of the cables going through the

hole so that it covered the hole to keep chips out of it. See figure 5.

Figure 5: chip

shield

I

mounted the box for the electronics on the back right of the base. I ran the stepper motor cables into the

electronics box from under the bottom and connected them to the driver.

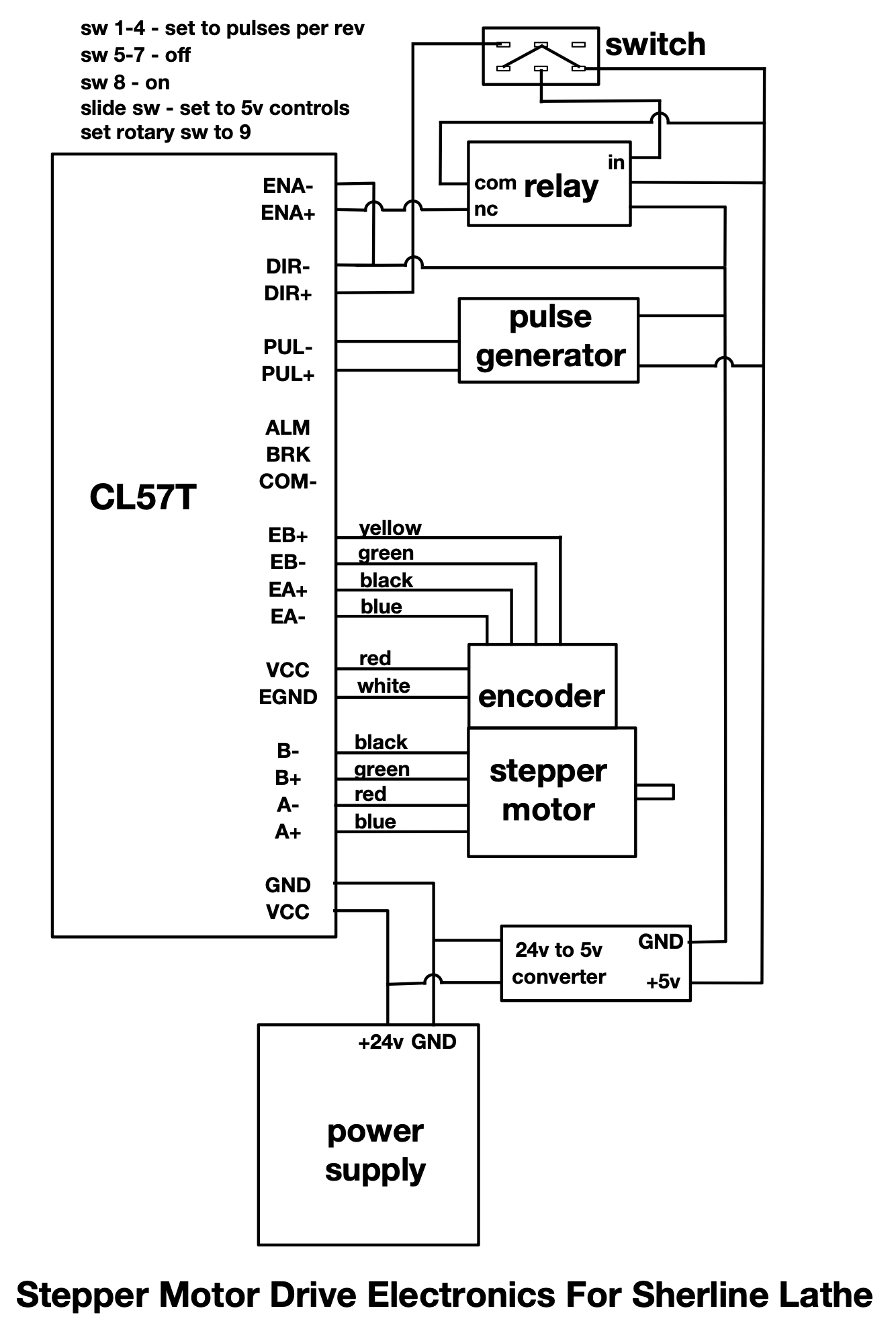

Figure

6 shows a diagram of the electronics for the stepper motor drive.

Figure 6: electronics

diagram for closed-loop stepper motor

Finally,

I mounted the switch and pulse generator module on the bracket under the lathe

bed and connected them to the electronics box. See figure 2 in Sherline Lathe

Infrastructure.

Stepper

motor speed

The

pulse generator is used to control the speed of the spindle motor. The speed can be set to anything between

barely moving to more than 2,000 RPM. Note that you cannot start the motor if

the speed is above about 500 RPM since it will stall. Instead, if you need a high spindle speed,

you start it at a slower speed and increase the speed while its running. You should also slow the motor down before turning

it off to minimize the stopping jerk and to set the pulse generator to a speed

lower than 500 RPM for the next time you start the motor. Note that you should not switch directly

between forward and reverse directions, you should stop the spindle before

switching to the other direction. If switch 8 on the CL57T is set to on the

motor starts more reliability but there is a few second pause between when you

turn on the switch and when the motor actually stars.

Stepper

motor speed vs torque

One

thing to keep in mind about stepper motors.

Stepper motor output torque inversely proportional to the speed. I.e, the

peak torque is at low speed and the faster you go the less torque the motor

puts out. So, if you want cutting power

on a lathe with a stepper motor drive, you want low RPM.

Little

Machine Shop provides a calculator as to

what spindle speed

should be used when turning particular materials on a lathe. It is quite useful but you need keep in mind

the torque curve of the stepper motor when deciding what spindle speed to

actually use and what depth of cut to make.

Parts

list for stepper motor drive

I’ve

included links for the parts at Amazon.

The same parts are available from other suppliers if you would rather

not deal with Amazon.

CL57T Closed-loop

Stepper Driver and Stepper Motor Kit

Mounting bracket

for the stepper motor

timing pulleys (2)

– 80 tooth, 8mm bore, for 6mm belt

Copyright

Ó 2024 Scott

Bradner

2024-09-05