Spindle

Wrench for a Sherline lathe

I

have found that Sherline’s Tommy Bars are too short,

too thin and too bendable to be useful for some functions. In particular I have a lot of problems using

one of them on the lathe spindle to tighten or remove a chuck. I made some stronger, longer and bigger tommy

bars (see separate article) but they were

still not ideal for the spindle. So, I

made a wrench that fits closely over the spindle, is very strong, and easy to

hold. (The wrench works on the mill as well.)

Figure

1 shows the wrench I made.

Figure 1: spindle

wrench

I

cut the wrench out of a piece of ¼ inch 6061 aluminum with a band saw. I cut the half circle at the left with a hole

saw before cutting out the rest of the wrench.

The hole saw was 1 1/8 inch in diameter, which is a little larger than the

diameter of the spindle on the Sherline lathe. In my

case, I made a 9” long wrench but, of course, you can make one of any length

that is best for you.

I

worked all of the edges of the wrench with the sanding belt on the back side of

a belt sander to remove any sharp edges. (I.e. the sanding belt without a

backing, so it is flexible and will conform to curves.)

I

then drilled a 4mm hole 1 ¼ inches deep in the middle of the circle. The hole was centered in the ¼ inch thick

aluminum. I then drilled a # 36 hole

perpendicular to the 4mm hole and tapped it for a 6-32 set screw. See figure 2.

I put a piece of 4mm steel rod in the hole such that about ¼” stuck out

of the end of the hole and put a set screw into the perpendicular hole to keep

the rod from sliding out.

Figure 2: set

screw hole

One

feature of the Sherline spindle is that the Tommy Bar

hole in it is not centered in the ¼” wide projection of the spindle from the

headstock body. The hole is a bit closer

to the headstock body. To deal with this

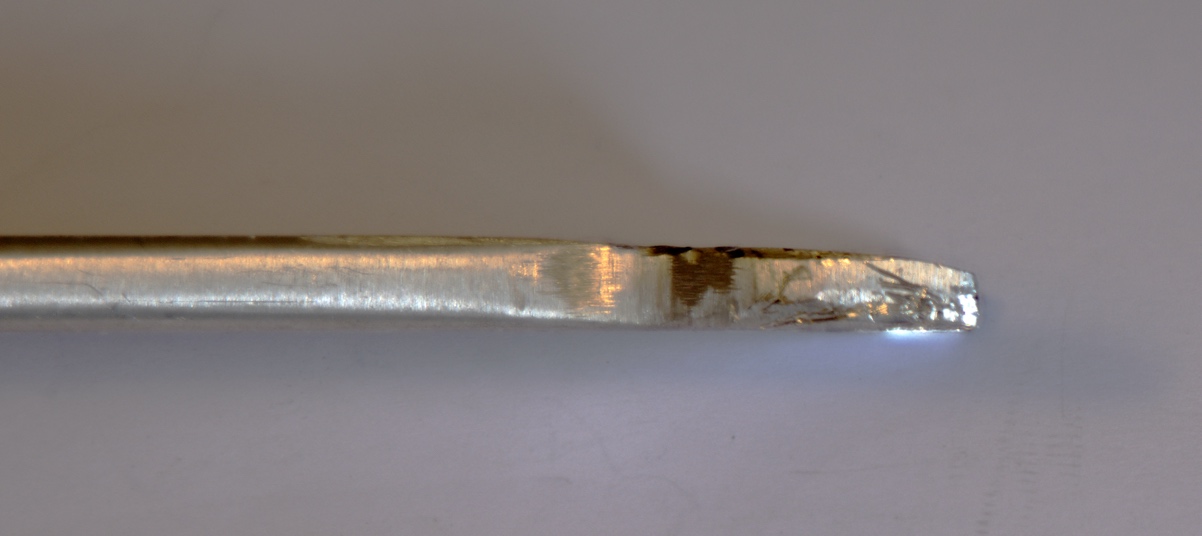

I put a taper into the end of the wrench by sanding one side of the end of the

wrench so that the pin would easily go into the hole in the spindle. See figure 3.

Figure 3: taper at

the end of the wrench

Copyright

Ó 2024 Scott

Bradner

2024-09-05