ER

Collets for a Sherline Lathe

ER

style collet holders for a Sherline lathe

If

you are working with round metal stock on a lathe then collets are useful, if

you are working with round stock that is soft, such as wood, collets are an

imperative. The former is because

collets hold stock far more securely than the jaws of a chuck do. The latter is because softer material gets

dented by the chuck jaws and can almost never be held true or, if taken out and

reinserted, will never be in the same angle.

Sherline sells a collet holder and

collets

for use on its lathe. The collets Sherline sells are WW style collets, a type often used by

jewelers. See figure 1 to see this type of collet.

Figure 1: Sherline WW collets

I

have two issues with this type of collet as used on the Sherline

lathe. First: the collets are for small

stock only. The Sherline design has the body of the

collet inside the headstock. Since the

hole though the headstock where the collet and its holder have to fit is less

then 1/2” in diameter the collets are severely limited in size. Sherline says that

the largest stock that can fit through one of these collets and the headstock

is 3/16” and the largest collet they sell is 5/16”. Second: this style of

collet only grips the stock at the tip of the collet which does not provide for

much gripping surface.

ER

collets have a very different construction.

See figure 2.

Figure 2: ER Collet

The

pattern of cuts means that an ER collet grips the stock along its entire length

providing a far stronger grip than the WW collets do. ER collets come in a bunch of standard sizes:

ER8, ER11, ER16, ER20, ER25, ER32, ER40 and ER50. The number represents the wide part of the

collet in mm. Within each size, the

individual collets come in different sizes.

The minimum size for most forms is 1/16” and the maximum size is

determined by the diameter of the collets in that form. Thus, the maximum standard sizes for the

forms are: ER8 – 3/16”, ER11 - 5/16”, ER16 - 3/8”, ER20 – 1/2”, ER25 5/8”, ER

32 – 7/8”, ER40 – 1 1/8”, and ER50 – 1 5/16”.

Sets

of ER collets range greatly in price but very good quality sets can be found

for very reasonable prices. For example,

I found a set of ER16

collets

from 1/8” to 23/64ths” by 64ths for only $79.

I

decided that I wanted to be able to use ER collets on my Sherline

lathe so went about figuring out how to do that.

ER

8 and ER11

For

the smaller ER collets I found that some manufactures make ER8 holders and ER11 holders mounted on the

WW collet stems that Sherline supports. See figure 3.

The ones I found have 3/16 holes through them so can be used with long

stock, if the stock is that small.

Figure 3: ER 8 and ER11 collet holders on WW collet

stems

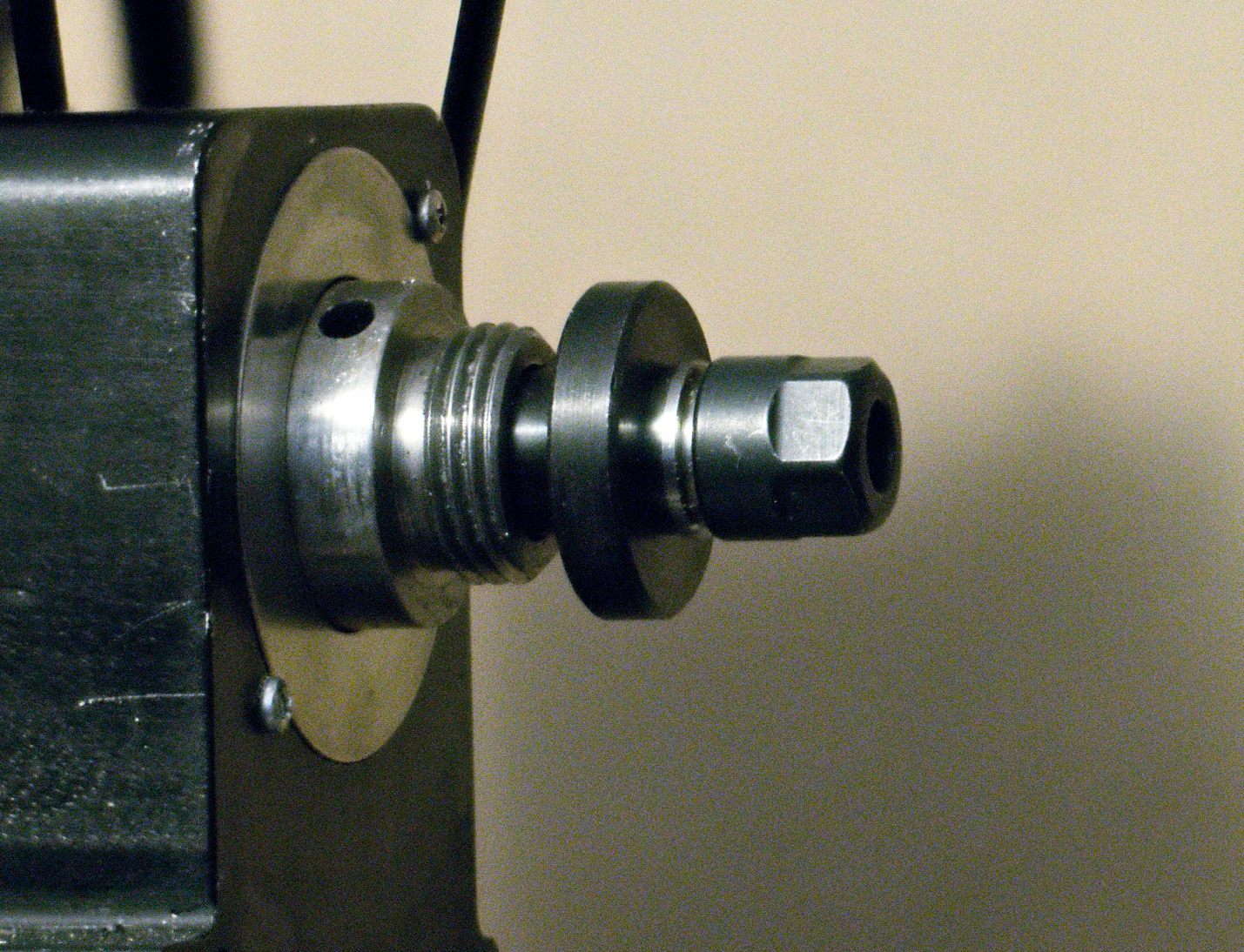

Figure

4 shows one of these ER8 holders mounted in a Sherline

lathe.

Figure 4: WW

collet-based ER8 holder mounted on a Sherline lathe

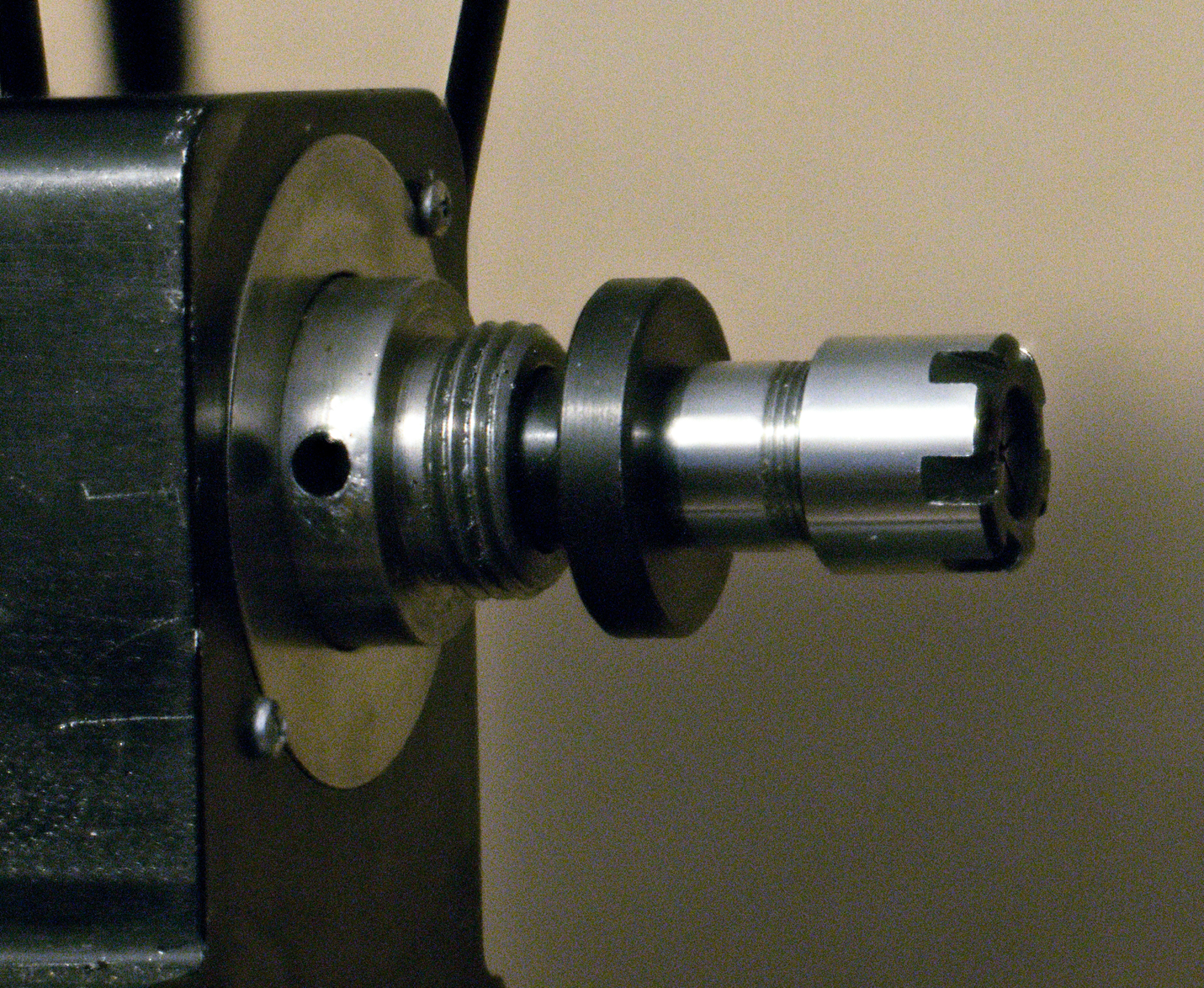

Figure

5 shows one of the WW collet-based ER11 holders mounted on a Sherline lathe.

Figure 5: WW

collet-based ER11 holder mounted on a Sherline lathe

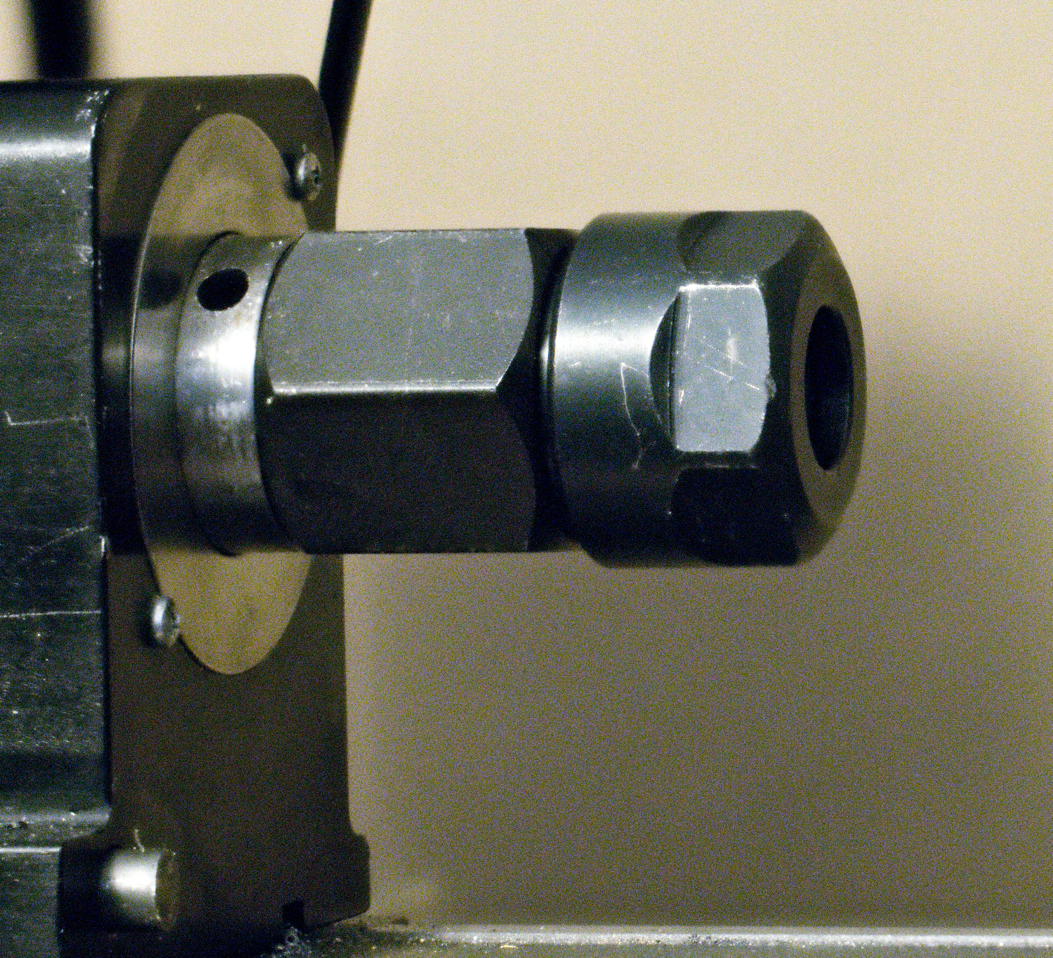

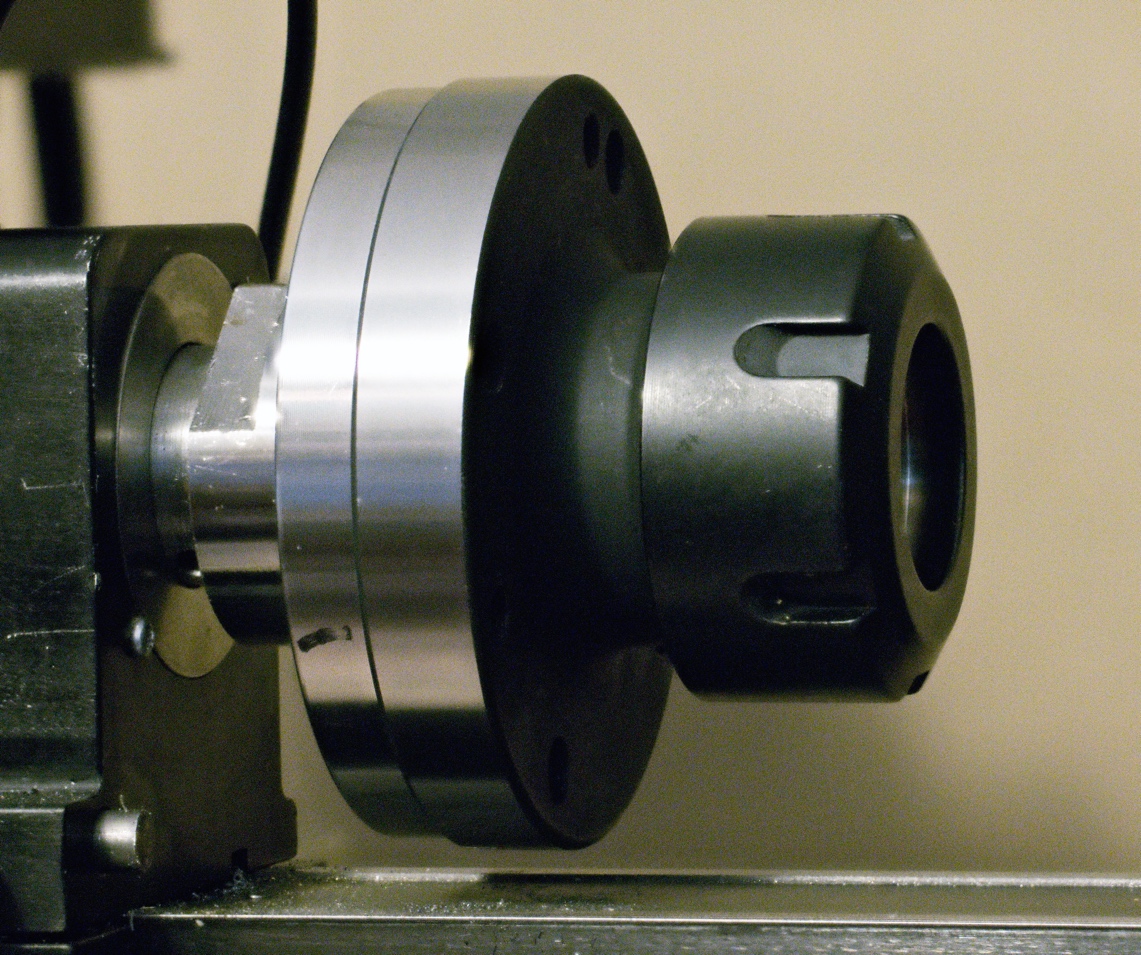

I

was able to find an ER16 holder with the same

thread as the headstock spindle on the Sherline lathe

( 3/4-16) see figure 6

Figure 6: ER16 holder with a 3/4-16 thread

Figure

7 shows the ER16 holder on the lathe.

Figure 7: ER16

holder mounted on a Sherline lathe.

It

took some work to get the larger ER holders to work on the lathe. I was able to find a ER20 holder and a ER25

holder that were designed to be attached to a rotary table. Figure 8 from the Amazon web site shows the

ER20 model, the ER25 model looks about the same.

Figure 8: ER20

holder

The

ER20 and ER25 collet holders have a small ring on the bottom that is used to

align them with the rotary table. This

is shown in figure 9, also from the Amazon web site.

Figure 9: back of

ER20 holder

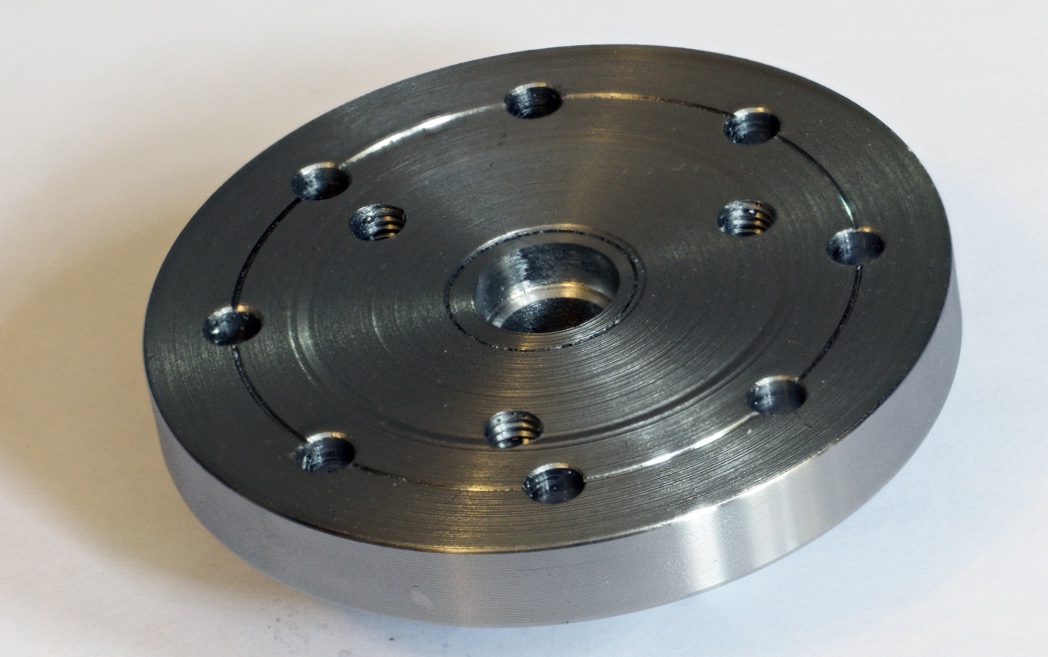

I

used that ring to align the ER20 and ER25 collets on faceplates that had a ¾-16

tread on them so they could be screwed onto the lathe spindle. Figure 10 is a picture from the Amazon

website that shows a faceplate as it comes from Amazon.

Figure 10: 3-inch

steel faceplate

I

got 3 faceplates, one each for the ER20, ER25 and ER32 collet holders. Figure

11 shows the back of the faceplates.

Figure 11: back of

3-inch steel faceplate

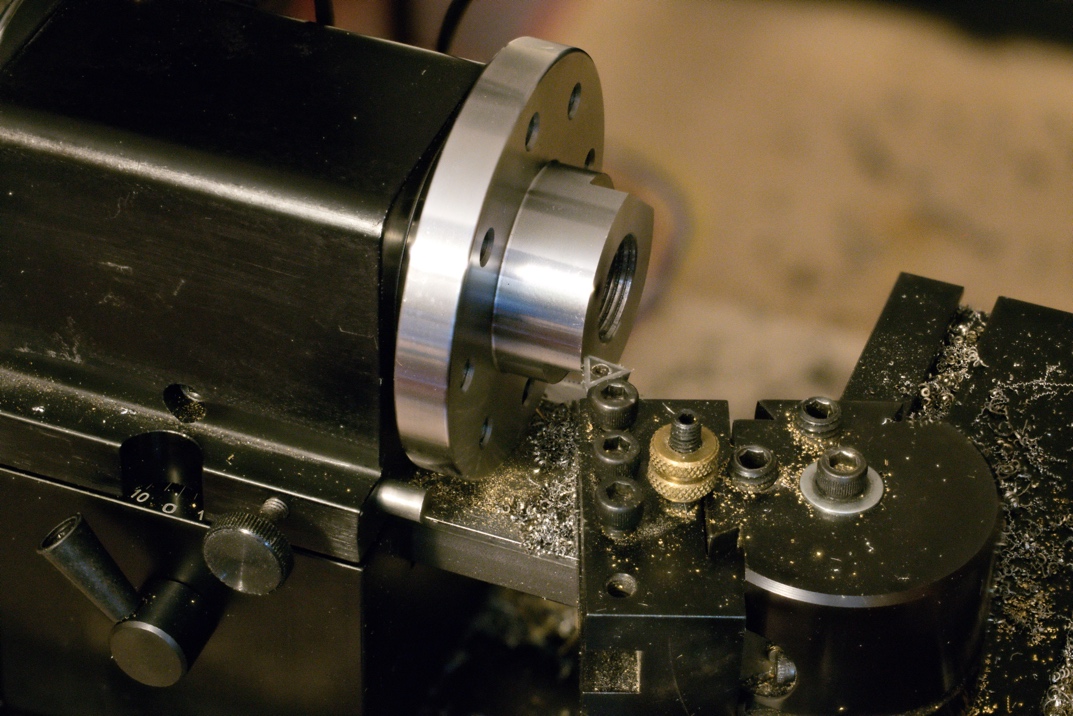

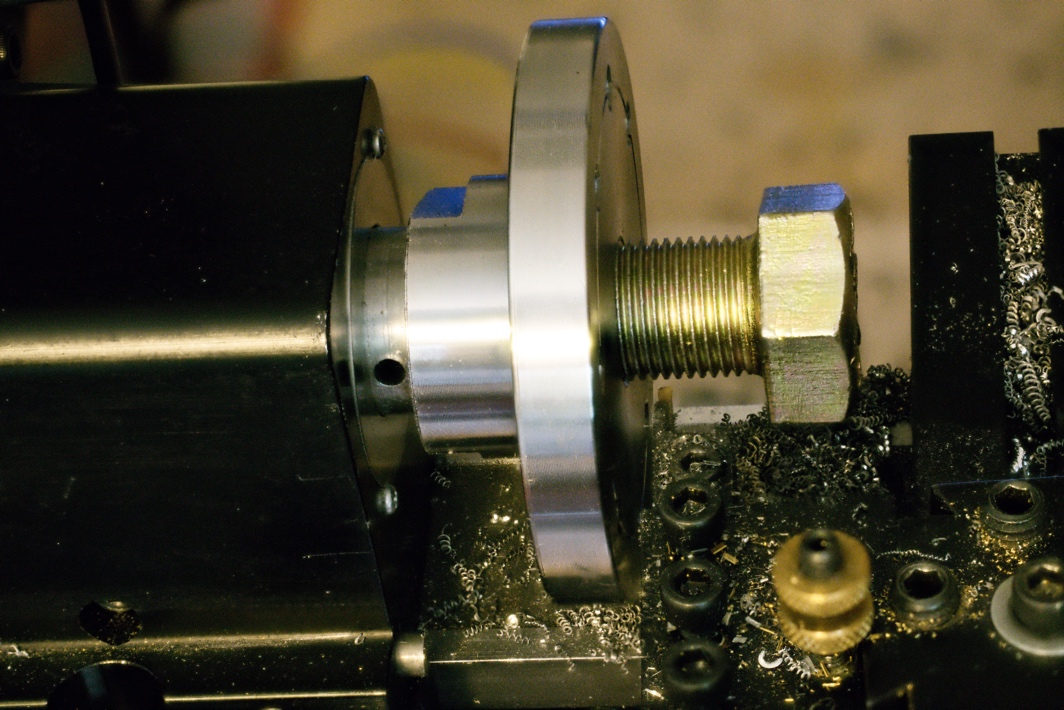

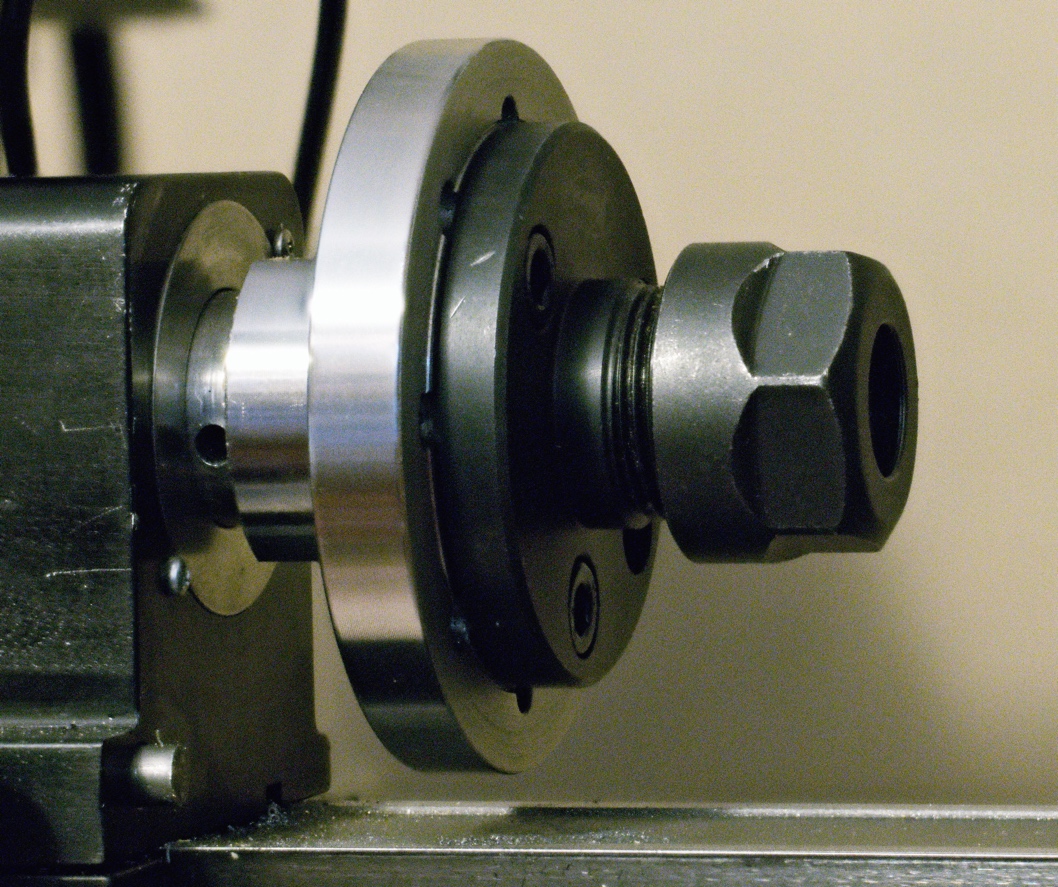

The

first thing I needed to do was to cut the hub down to the top of the threads so

that it would engage the threads on the Sherline

lathe spindle. I did this on the Sherline lathe by

screwing the plate onto the spindle with the flat side towards the lathe. Then

I just cut down the excess material. See

figure 12

Figure 12:

machining a faceplate hub

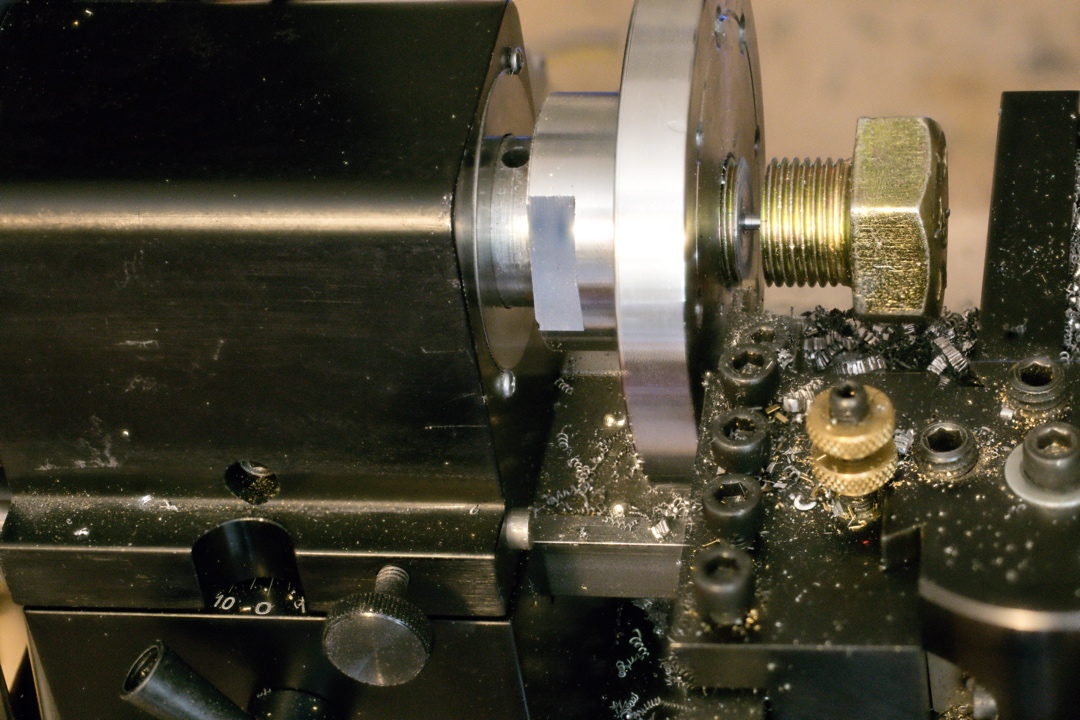

I

needed to make a hole the diameter of the ring on the collet holders for the

ER20 and ER25 collet holders. To do that I first had to fill the hole that was

there. I did this by screwing a ¾-16

bolt into the hole after mounting the plate on the lathe. I put a 1/16 thick washer in the hole first

so that there would be a gap between the bolt and the lathe spindle. I also covered the bolt with permanent thread

lock before screwing it into the plate. Figure 13 shows the bolt in the plate.

Figure 13: 3/4-16

bolt in faceplate

I

then cut off the bolt head. See figure

14

Figure 14: bolt

head almost cut off

I

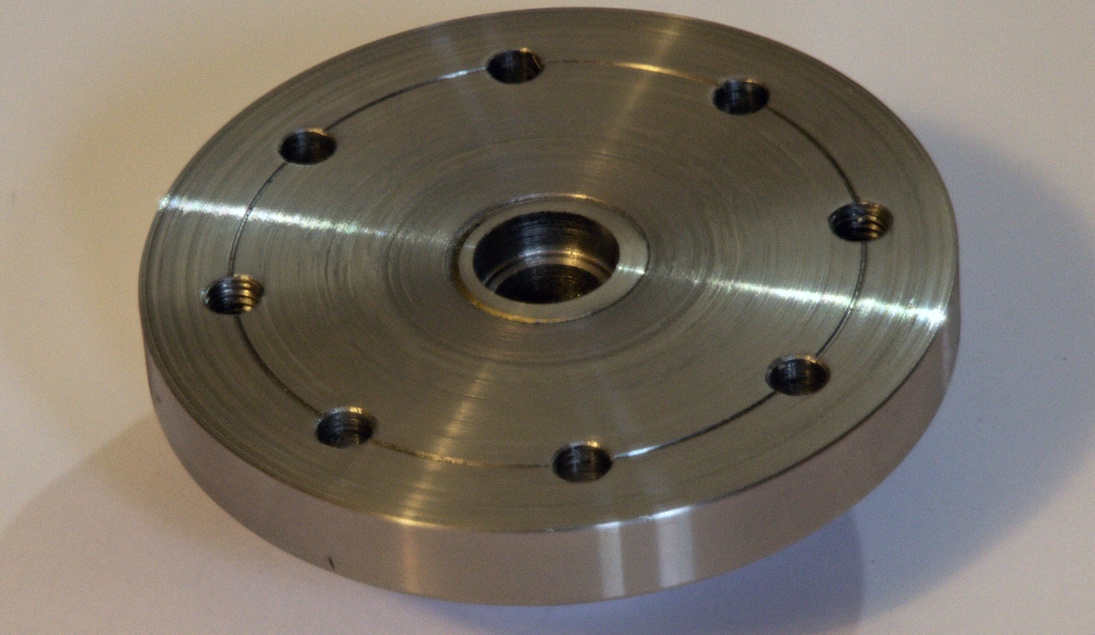

then cut the remaining bolt to match the plate and made a hole in the bolt the

diameter of the flange on the collets. See figure 15.

Figure 15:

finished faceplate

As

can be seen in figure 125, the plate has a ring of holes. The holes are the right size for a M6

tap. In the case of the ER25 collet

holder, two of the holes lined up perfectly with holes in the holder. I just had to tap those holes with a M6 tap

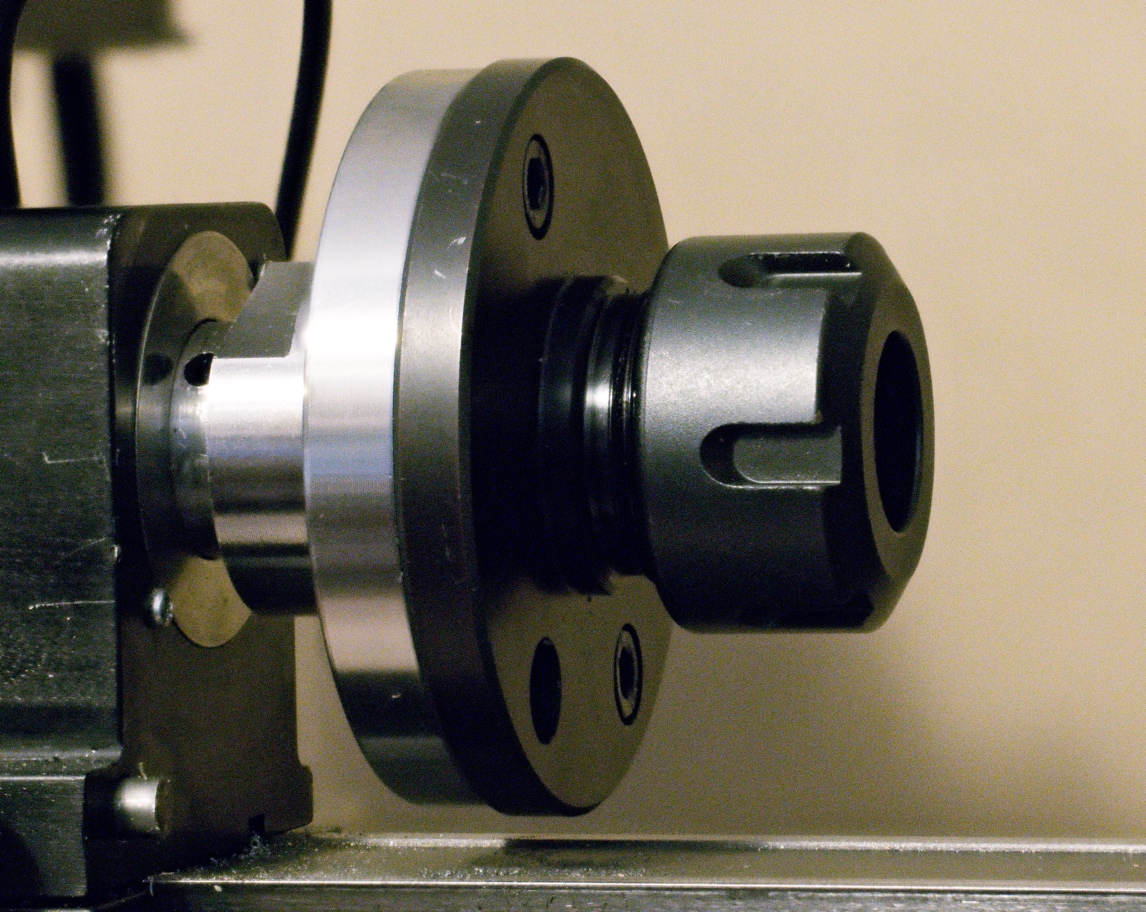

and use two short M6 bolts to hold the collet holder to the plate. Figure 16 shows the ER25 holder bolted to the

plate and mounted on the lathe.

Figure 16: ER25

holder attached to machined faceplate & mounted on lathe

The

holes did not line up for the ER20 so I had to drill three new holes in the

plate that lined up with the mounting holes in the ER20 collet holder and tap

them for M6. See figure 17.

Figure 17:

faceplate for ER20 holder with mounting holes

Figure

18 shows the M20 holder bolted to its plate and mounted on the lathe.

Figure 18: ER20 holder

bolted to faceplate & mounted on lathe

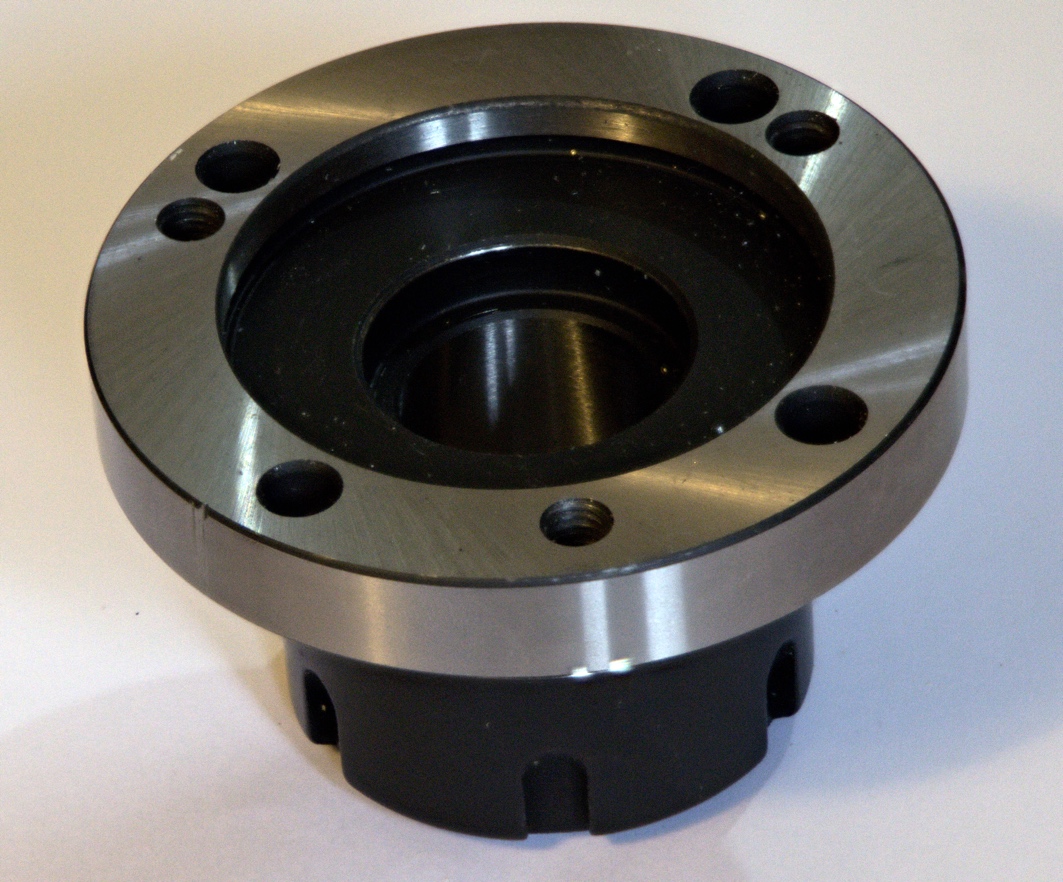

The ER32 collet holder is constructed

differently. It does not have the ring

shown in figure 9, instead it has a ridge around the outside. See figure 19.

Figure 19: bottom

of ER32 holder

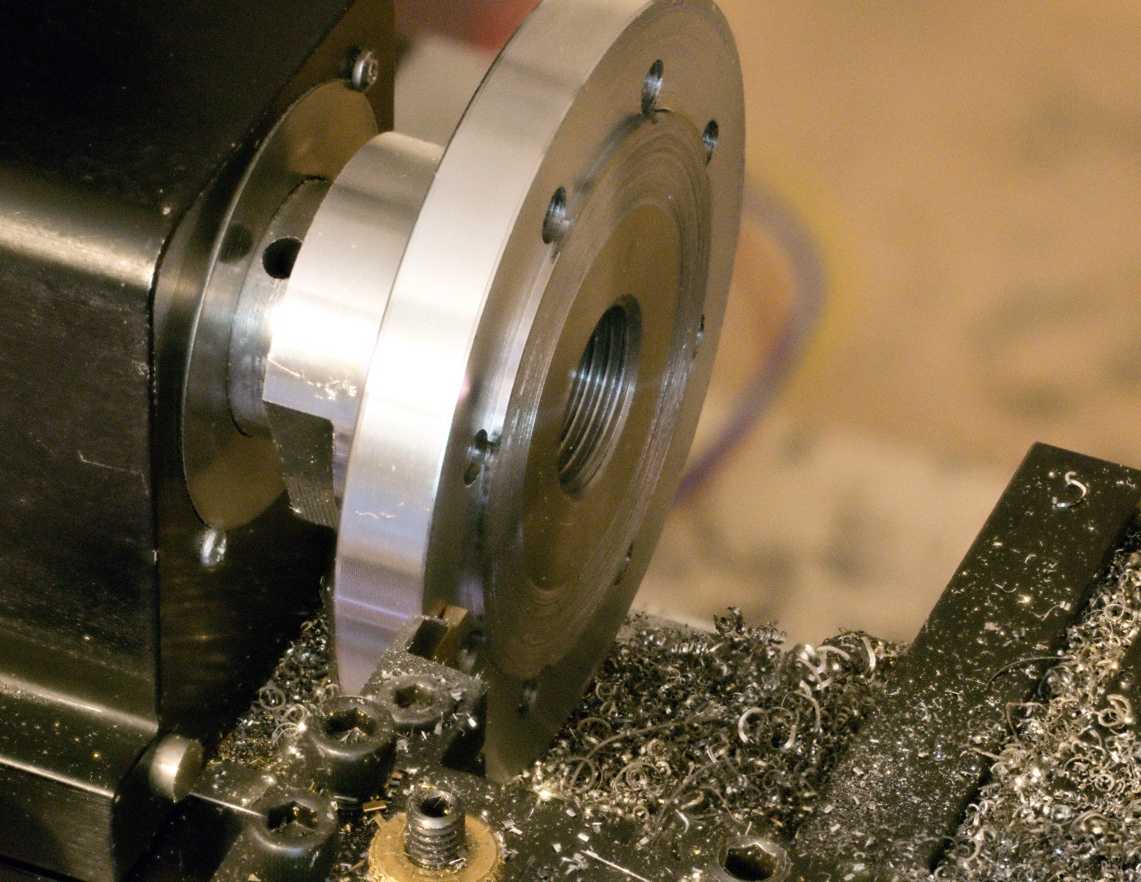

I

turned the plate for the ER32 collet holder to have a profile that fit in its

base. See figure 20 to see the profile being cut.

Figure 20

faceplate for an ER32 holder

I

then drilled and countersunk three holes in the back of the plate to match the

three M6 tapped holes in the ER32 collet holder. I did not do a good job so I’m not going to

show you the result, but figure 21 shows the ER32 collet holder bolted to its

plate and mounted on the lathe.

Figure 21: ER32

holder bolted to a faceplate & mounted on lathe

There

is another option for ER11, ER16 and ER20 collets. You can get those collet holders with MT1

tapers, the taper that is used in the Sherline

headstock spindle. See figure 22.

Figure 22: MT-1 based ER collet holders

To

use these collet holders on a Sherline lathe (or

mill) you need to get a long M6 bolt and make a retainer stop (the small brass

piece at the left of figure 22). The

disadvantage of these holders is that they have no through hole so can only

deal with short material. To me, these

holders are better suited to for holding tools in a Sherline

mill than for use on a lathe.

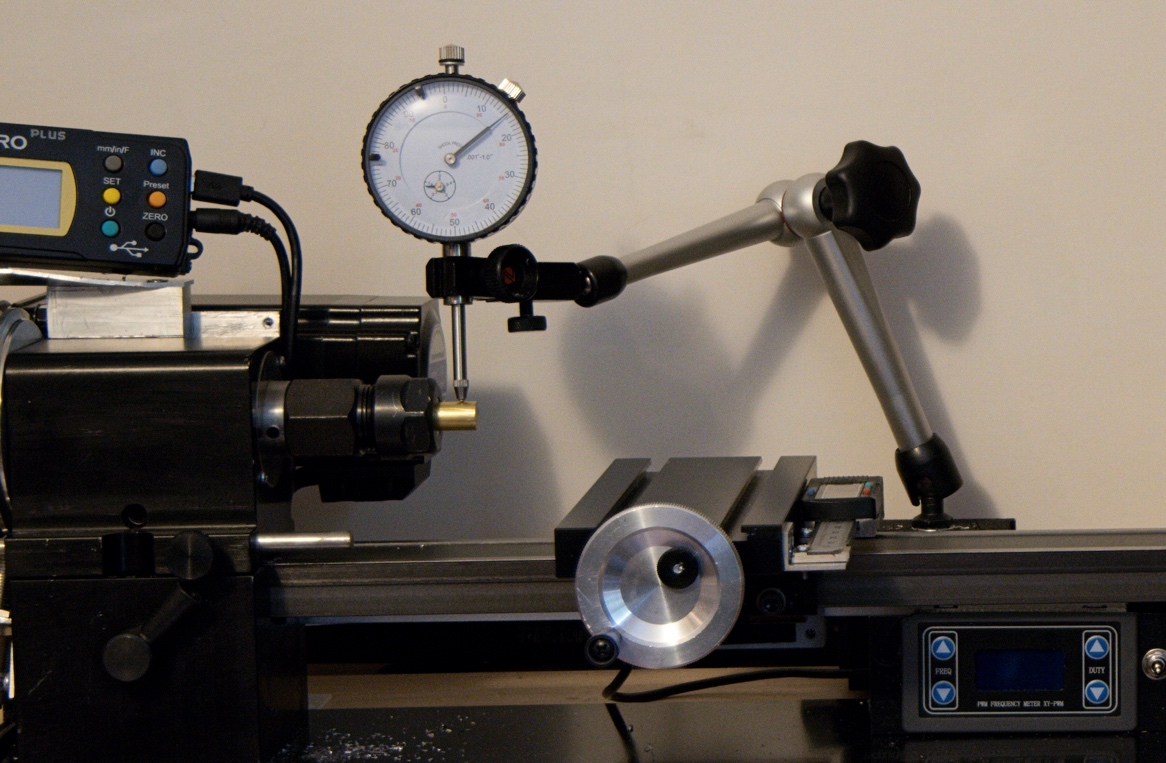

I

ran some tests to check the runout for the collet holders. Figure 23 shows the test setup I used.

Figure 23: runout

testing setup

The

following table shows the results of the runout tests

|

Sherline lathe Spindle |

± 0 |

|

Sherline ww collet

holder ER8 collet – 3/16” stock |

± 0.0035 |

|

Sherline ww collet

holder ER11 collet – 1/4” stock |

± 0.00425 |

|

ER16

collet holder – 3/8” stock |

± 0.0005 |

|

ER20

collet holder – 1/2” stock |

± 0.0025 |

|

ER25

collet holder – 5/8” stock |

± 0.0025 |

|

ER32

collet holder – 3/4” stock |

± 0.00225 |

|

ER11

collet holder – MT1 – 1/4” stock |

± 0.0045 |

|

ER16

collet holder – MT1 – 3/8” stock |

± 0.0015 |

|

ER20

collet holder – MT1 – 1/2” stock |

± 0.002 |

|

Sherline 3-jaw chuck –

1/2” stock |

± 0.002 |

|

Sherline self-centering 4-jaw

chuck – 1/2” stock |

± 0.008 |

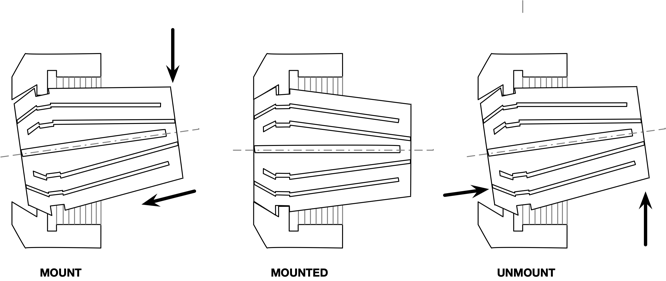

For

those of you who have not used ER collets before, a word of warning. The collet needs to be set in the holder nut

before putting it into the holder body.

As shown in figure 24, you put the collet in the nut at an angle then

flatten it out until it clicks. You do

the reverse to get it out, tilt the collet until it gets free of the nut on one

side then rock it free.

Figure 24 –

Mounting and unmounting an ER collet

If

properly done, the top of the collet will be even with the top of the nut or

even a bit above the nut as shown in figure 25.

If you put the collet in the holder first then try to tighten down the

nut, the top of the collet will wind up below the top of the nut and it will

not be grabbing the stock correctly.

Figure 25 – properly

seated collet

Parts

list

Sherline WW collet holder

and collets

WW collet-based

ER8 collet holder

WW collet-based

ER11 collet holder

ER20 Holder for a Rotary Table

ER25 Holder for a Rotary Table

3 inch Steel Faceplate

with a ¾-16 Spindle Thread

Copyright

Ó 2024 Scott

Bradner

2024-09-05