Boring

Bar Holder for a Sherline Lathe

I

have the boring bar holder for the Sherline quick-change tool

post

for my Sherline lathe. I find that it is quite hard to use it. Specifically, when I use a boring bar in the

holder the tool post rotates under normal use.

This causes the bar to back away from the cutting point. This happened no matter how hard I try to

tighten the hold down bolt for the tool post.

I

decided to make my own boring bar holder that would not rotate.

The

way that I ensure that the holder will not rotate is that I have two tie-down

bolts that use the same channel in the crossslide.

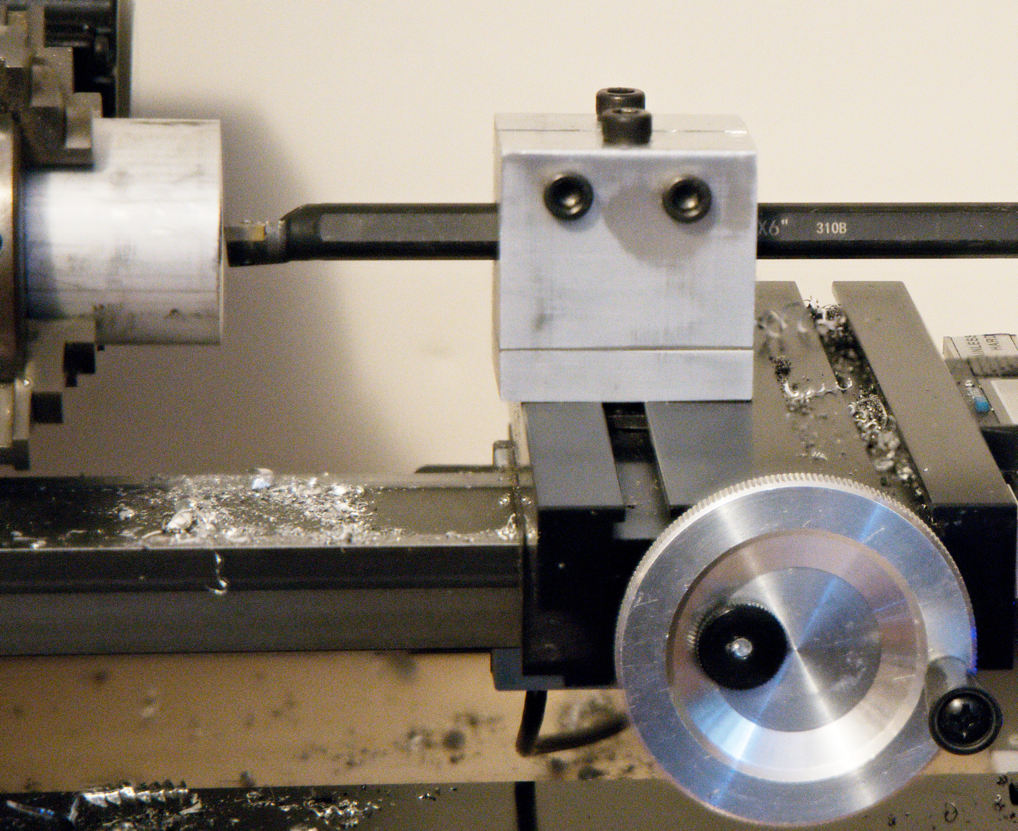

Figure

1 shows the holder mounted on the crossslide of a

lathe.

Figure 1: boring

bar holder on lathe

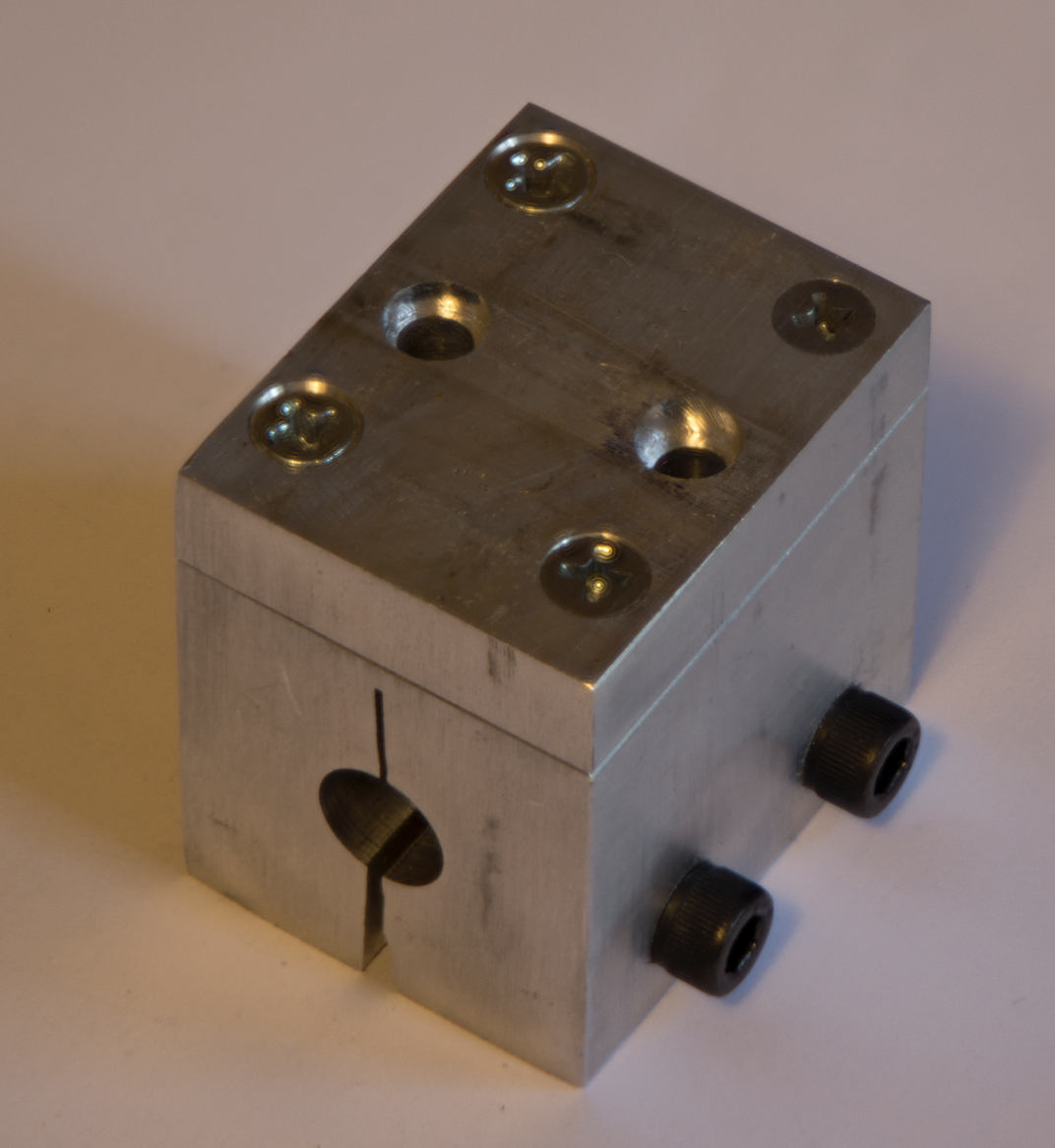

I

started with a 1 ¼” x 1 ¼” bar of 6061 aluminum. I cut off a 1 ¼ “ long

piece (making a cube) and drilled a 3/8 hole through the center. Since the 1 ¼” height of the bar does not

position the center of the hole at the right height. I added a piece of 5/16” thick aluminum to

the bottom of the cube and that provides the right amount of height. See figure 2.

Figure 2: bottom

of boring bar holder

You

can see in Figure 2 that there are two holes for hold down bolts, one on each

side of the through hole, that use T nuts to hold the holder to the crosslide. Note that

these holes are #11 (body drill for 10-32 screw) and are counter bored from the

bottom to ¼” to a depth of ¼” to clear the T-nuts. The hold down bolts are 1

3/4 “ long. You can also see the slot I made

perpendicularly through the 3/8” hole down to just above the bottom of the

cube. (The top of the slot is rather

messy because I tried to use a slotting saw first and that made a mess – I used

a band saw to cut the bottom part.) You

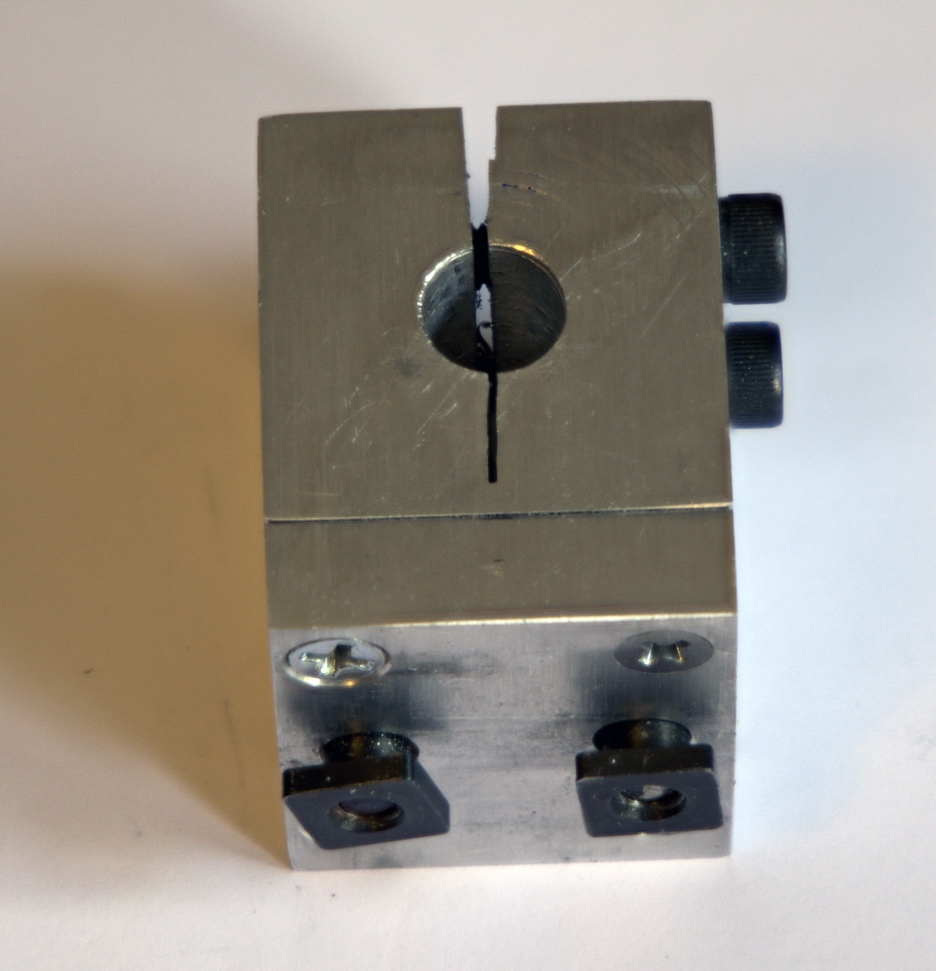

can also see the slot in figure 3.

Figure 3: side

view of holder

The

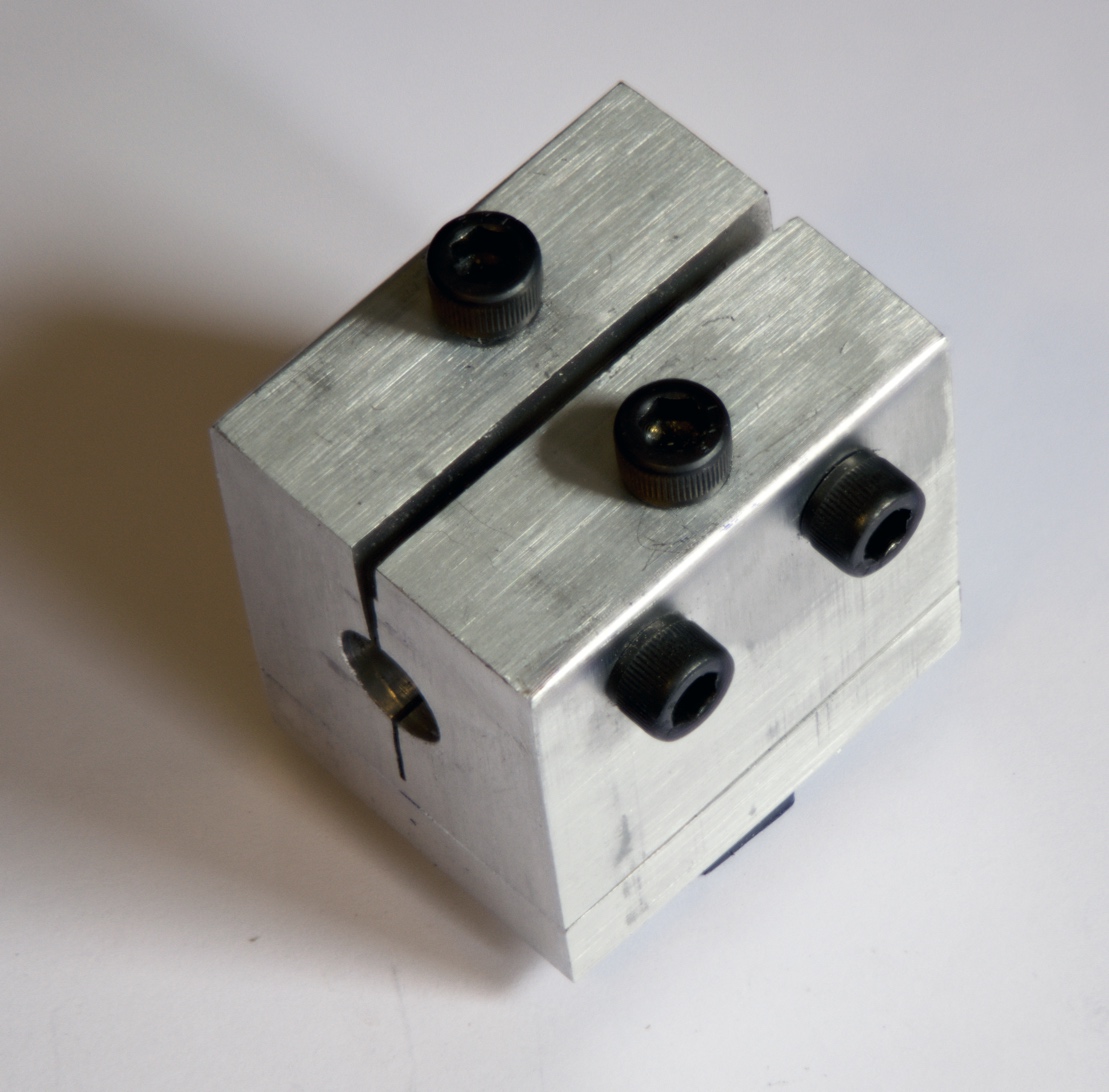

final part of the holder is the clamp that holds the boring bar in the

holder. This can be seen in figure 4.

Figure 4: top view

of holder

You

can see the two bolts at the top going across the slot. The part of the holes to the right of the

slot are #11 (body drill for 10-32 screw), the parts of the holes to the left

are tapped 10-32. Thus, a tightening the

two bolts going across the slot will close the slot and clamp down on the boring

bar in the through hole.

To

use the holder, you first slide the holder into a slot on the lathe crosslide and tighten the hold down bolt furthest away from

you. Then insert the boring bolt and tighten the two clamp bolts to secure the

boring bar. Finally, you tighten the

other hold down bolt.

Copyright

Ó 2024 Scott

Bradner

2024-09-05