Belaying

Pins

I

decided to try to make the belaying pins for my model. I chose a method based on the one that Edward

Tosti describes on pages 34 to 41 of volume 2 of his

3-volume set of books on modeling the Young America.

Tosti ‘s method involves turning small brass

rods in a hardened steel form then blackening the result.

Belaying

pin size

I

chose to use 1.2mm brass rod. That

results in a belaying pin that is not actually to scale since 1.2 mm is 0.047

inches which is 4.54 inches at 1:96 scale.

Belaying pins should be closer to 2 inches in diameter than 4.5. 9 See this belaying pin

from about 1929

which is about 2” in diameter and 17 inches long. But since I had already

drilled holes in the in pin and fife rails based on some purchased belaying pins I was originally going to use I was stuck with the

larger size. True sized model belaying

pins would be made from 0.020 brass wire, which is even smaller than the 1/32

wire that Tosti used.

The Tosti method will work with just about any

sized wire as long as you make the filing guides to accommodate the size rod

you select.

Filing

Guides

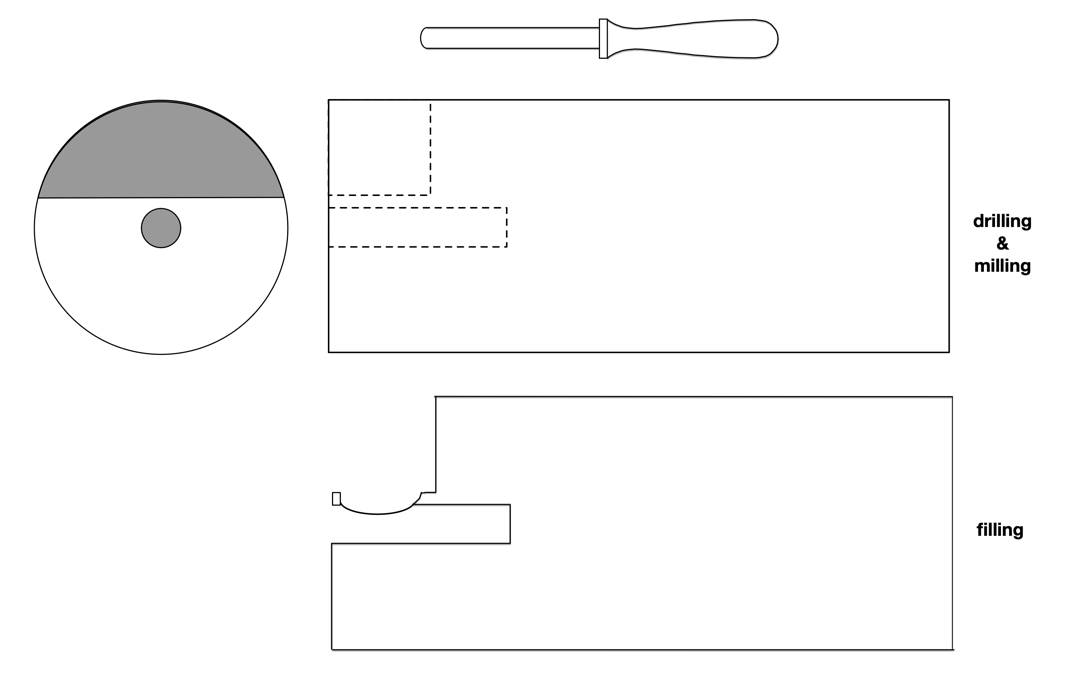

I

used two filing guides. The first is for

the pin’s handle and the second is for the pin’s shaft. Tosti used one combined guide but I thought that two would

be easier. The filing guides I used can be seen in figures 5 and 6.

I

made the filing guides from 1/4” high carbon steel rods. Both guides were made

in the same way. First, I cut off a

small piece of rod, about an inch long, then using the lathe and a center drill

as a starter I drilled a 1.3 mm hole in the center of the rod (slightly larger

than the rod I am using). For the handle

guide, the hole was about 0.093” deep which covered the handle and a bit

more. For the shaft guide, the hole was

0.3” deep but could have been deeper without any issue. This filing guide

covers more than the full length of the belaying pin, providing enough extra

for the wire cutters to cut off the belaying pin when it’s done. Note that the belaying pin shape does not

need to be all that perfect because 1) most of them will be covered up by

coiled rope and 2) those that are not covered will be just little details in a

model that the viewer cannot get all that close to.

I

then took the pieces to the mill. For

the handle guide I cut a flat in the rod that extended down to just above the

hole – I left about 0.010 gap. I then

filed the steel down to intersect the hole where the narrow part of the handle

is. This left a narrow ridge where the

handle flange is. See figure 1. For

the shaft guide, I milled down to slightly below the top of the hole, to a

level that defined the diameter of the shaft. The location of the cut was such

that the edge was just below the handle flange. See figure 2.

Figure 1: Handle

filing guide

A

representative belaying pin from the mid 1800s is shown at the top of figure 1.

The two blocks shown in figure 1 represent cross sections of the high carbon

steel rod I used to make the filing guides.

The top block shows, in dashed lines, the hole I drilled into the center

of the rod and the part of the rod I cut off using the milling machine. The bottom block is a cross section showing where

I filed the guide to provide a channel to file the narrow part of the handle.

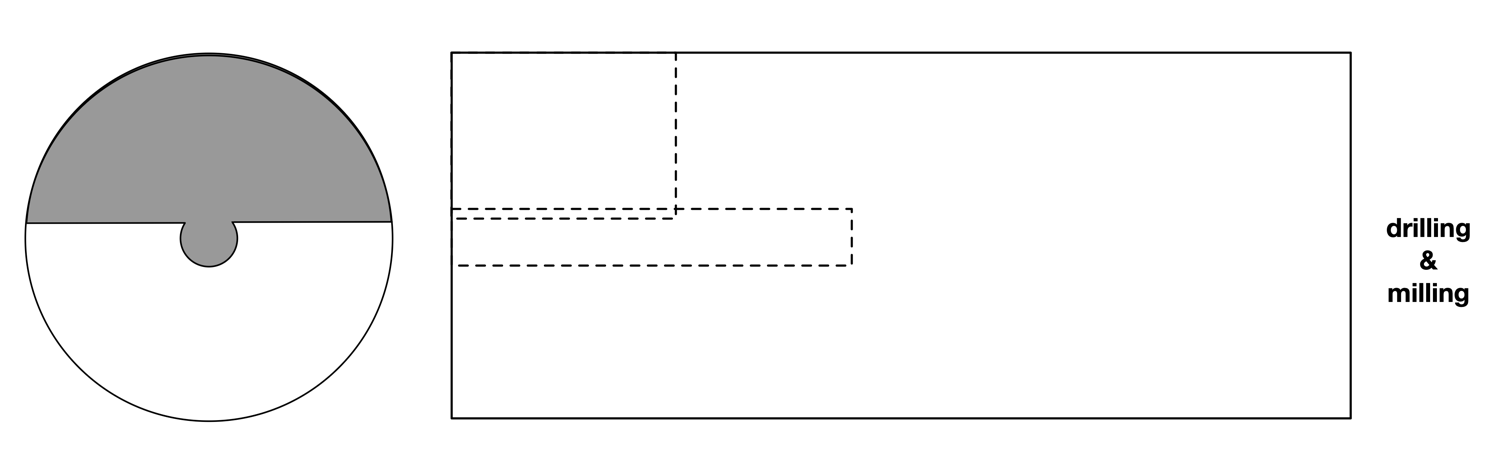

Figure 2: Shaft

filing guide

Figure

2 shows the hole and milling needed for the shaft filing guide. There was no filing needed for the guide,

just drilling and then milling.

I

did not include dimensions on figures 1 and 2 because you will need to decide

the dimensions for your guides based on the size rod you are using and the size

of the belaying pin you will be making.

I

then hardened the guides. (See separate article.) The hardening

was to make the guides resistant to the files used to shape the belaying pins.

The

hardened steel is resistant to the action of filing the brass rod but not

immune. I found that a filing guide

lasts between 100 and 150 pin ends so to make the required 270 pins I needed to

make two sets of filing guides.

Making

the Belaying Pins

I

cut 1.2mm brass rods into pieces between 1” and 1 1/4” long using wire

cutters. Each piece will make two belaying

pins. I then squared off the ends of the pieces using a small disk sander. I used a jig I made up from some scrap

wood. The slots at the top were the

width of the brass rod and made sure that the rod was square to the face of the

sander. It only took a few seconds to

sand each end of each rod. See figure 3.

Figure 3: Squaring

off jig

The

result is a pile of rods with squared off ends. See figure 4.

Figure 4: Rods

with squared off ends.

I

then treated the ends of the rods by mounting each rod in a Jacobs chuck on a lathe

and rounding off the end with a file. I found that hand tightening the chuck

was sufficient so the process went quickly, less than 20 seconds per end. See figure 4.

Figure 4 also shows the file that I used to round off the ends of the

rods. The file has a very fine cut so

that the rounded end is very smooth.

Figure 4: Rounding

the ends

This

resulted in a pile of rods with rounded ends.

See figure 5.

Figure 5: Rods

with rounded ends

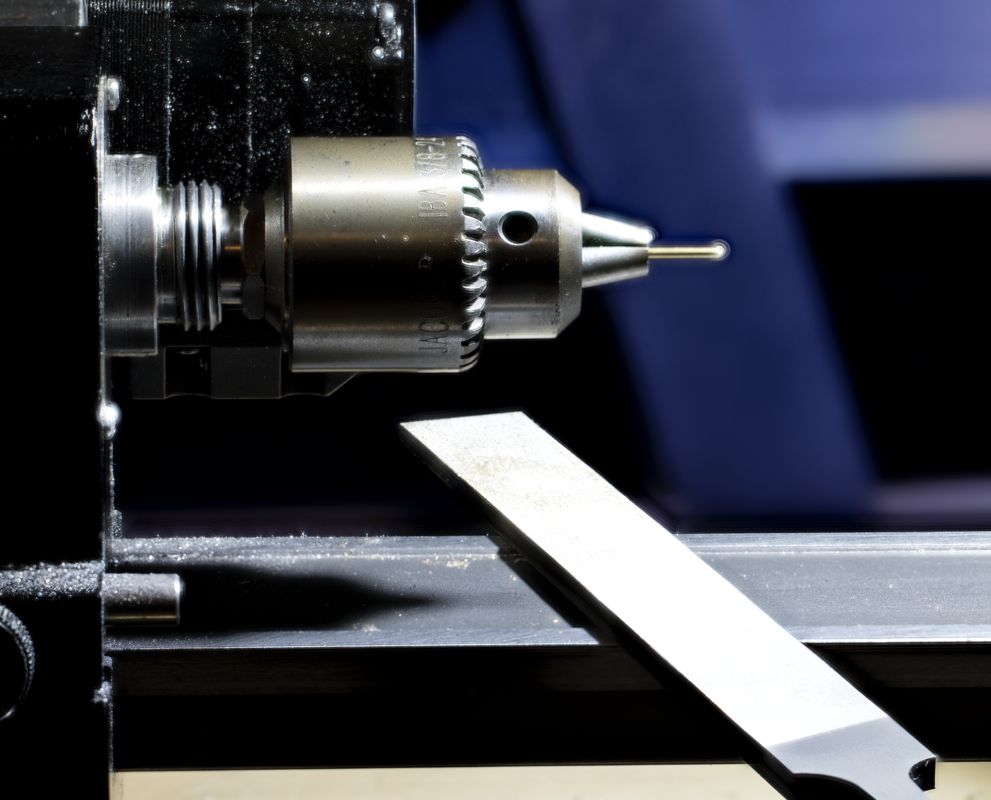

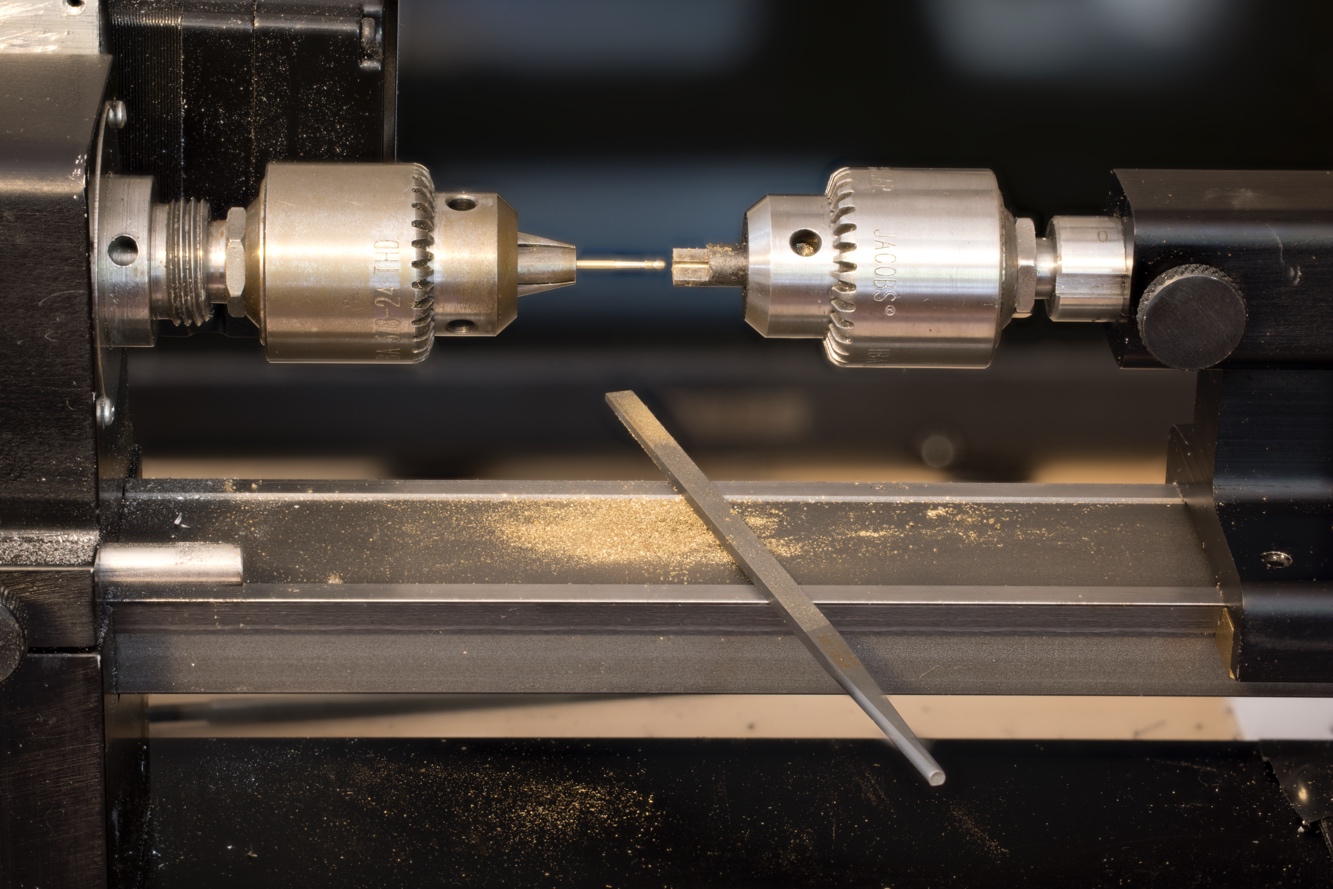

I

then formed the handle of the belaying pins using the handle filing guide. See figure 6 which shows the guide held in

the Jacobs chuck to the right, a rod that has been shaped held in the Jacobs

chuck on the left and the needle file use to shape the handle by filing in the

slot in the guide. The left Jacobs chuck

is on the lathe spindle and the right Jacobs chuck is on the lathe

tailstock. Note that I mounted the

tailstock to the left of the crosslide and that the

guide is held at an angle to make filing easier. The process was to mount the

rod in the left-hand Jacobs chuck and hand tighten the chuck. Then to slide the guide over the rod by

sliding the tailstock. Then locking the

tailstock in position, starting the lathe and commencing filing. I turned off

the lathe when the filing was done, unlocked the tailstock and slid it out of

the way so I could release the rod.

Repeat a lot of times with each filing taking less than a minute.

Figure 6: Shaping

the handles

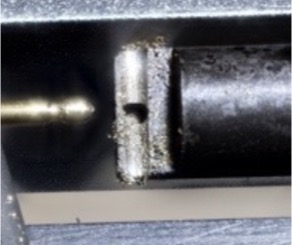

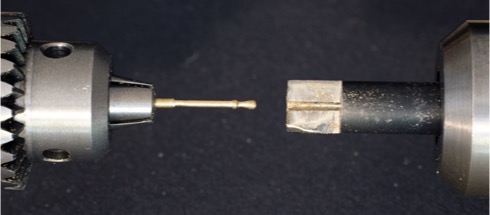

Figure

7 is a closeup of making the handle.

Figure 7: close up

from figure 6

The

result is a pile of rods with handles on each end. See figure 8.

Figure 8: Rods

with handles

I

then formed the shaft using the shaft filing guide. Figure 9 shows the shaft filing guide mounted

in the Jacobs chuck on the right, a rod with a formed belaying pin mounted in

the Jacobs chuck on the left and the file I used to shape the shaft.

Figure 9: Shaping

the shaft

Figure

8 shows the shaft filing guide in the right Jacobs chuck, a piece of 1.2 mm rod

with a shaped handle and shaft in the left Jacobs chuck and the file I used to

shape the shaft below them. It is hard to see in the photo, but the file does

not have any teeth on the edges, this means it makes a sharper shoulder on the

belaying pin. Figure 10 is a close up of

the guide and the shaped rod. Filing each shaft took about a minute.

Figure 10: close

up from figure 8 of filed pin and shaft filing guide.

The

result is a pile of rods with belaying pins on each end. See figure 11.

Figure 11: Rods

with pins on each end

I

cut the belaying pins from the rods with a wire cutter. That produced a pile of pins. See figure 12.

Figure 12:

Belaying pins before blackening

I

then blackened the pins. (See separate article.) See figure 13.

Figure 13:

Belaying pins after blackening

Figure

14 is a close up of one belaying pin.

Figure 14: Close

up of a belaying pin

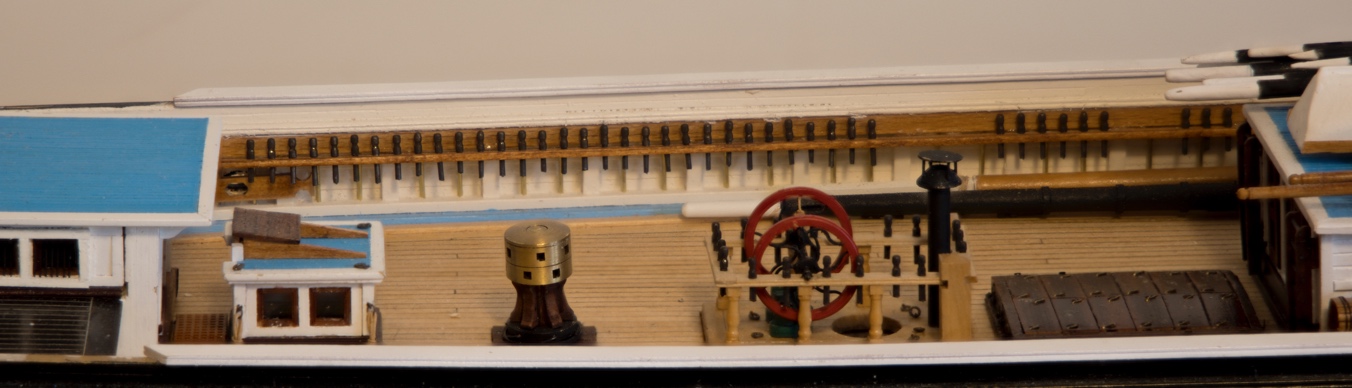

I

then installed the pins into the pin rails of the model. See figure 15.

Figure 15: Belying

pins installed in my model

There

is an alternative to making your own belaying pins. You can buy pins from

multiple fittings vendors. One example

is Bluejacket. They sell brass belaying

pins that are scaled for 1:96 models.

But the Bluejacket pins are rather pudgy as can be seen in figure 16.

Figure 16:

Bluejacket belaying pin (left) and my belaying pin.

At

scale, the Bluejacket pin is 5 ¾” in diameter at 1:96 scale – far too big for a

real person to handle. My pins are also

too big at 4 ½” scale diameter but, as I noted at the start of this article, I

had already drilled the holes for the belaying pins so had to make my pins

larger than they should be. That said,

considering that people will be viewing your model from at least a few feet

away, Bluejacket pins could look just fine.

Parts

list

Brass rod: (many sources)

note that you want rod, not wire,

because wire is too soft and not straight enough

High carbon steel rod: McMaster-Carr

Quenching oil: Brownwlls Tough-Quench

also available from some gun shops

Copyright

Ó Scott Bradner

2024

2024-10-02